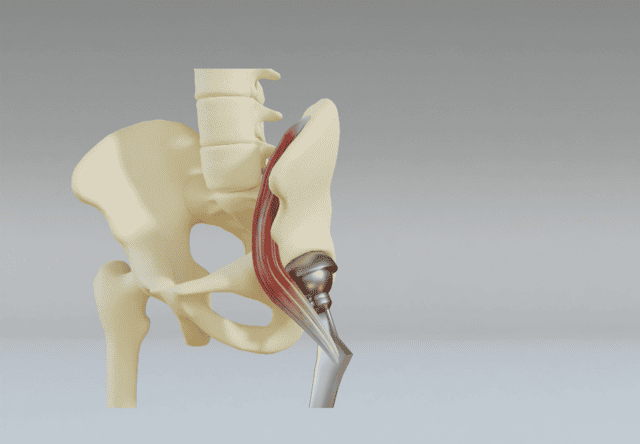

TU Delft researchers have developed a 3D printing technique that closely imitates the natural connection between bone and tendon. This method addresses the challenge of interfacing hard and soft materials, a common issue in various applications, including electronics. By studying human bone-tendon joints, the team from the faculty of Mechanical, Maritime and Material Engineering (3mE) sought to optimize these interfaces.

Their approach involved a unique multi-material 3D printing process and strategic geometries to enhance the contact area between hard and soft materials. This method not only reduces stress concentration at the interface but also mimics the gradual material transition seen in nature. The team achieved a 50% increase in the toughness of joints compared to a control group. This enhancement is pivotal, considering the lower tolerance of soft materials to force compared to hard materials. The research, led by Professor Amir Zadpoor and first author Mauricio Cruz Saldivar, has also yielded universally applicable design guidelines for improving the mechanical performance of such interfaces.

A novel aspect of this technique is its ability to produce entire products in one print, eliminating the need for adhesives or mechanical connections. This opens possibilities for combining diverse materials, expanding the application range to include medical devices, soft robotics, and flexible electronics.

“What we are trying to do is remove the extra steps that are involved, and have everything in one go,” said assistant professor Zjenja Doubrovski.

“That makes it possible for us to combine even more exotic materials together, for example, materials that have more damping resistance versus materials that are stronger.”

This research paves new paths for multi-material 3D printing, particularly in creating more resilient interfaces between hard and soft materials. The methodology could significantly impact medical, robotic, and electronic industries by offering more integrated and reliable material combinations. Further exploration into incorporating living cells into these interfaces could revolutionize regenerative medicine, opening up new frontiers in medical implants and tissue engineering.

Source: innovationorigins.com

Come and let us know your thoughts on our Facebook, X, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.