University of Glasgow researchers have made advancements in temperature sensing with the development of innovative ‘smart skin’ sensors. This breakthrough involves a soft, flexible material composed of carbon fibers and silicon rubber, eliminating the need for conventional batteries or onboard processing.

Operating on electromagnetic waves, the sensor absorbs and reflects radio-frequency signals, providing an unprecedented range for temperature measurement.

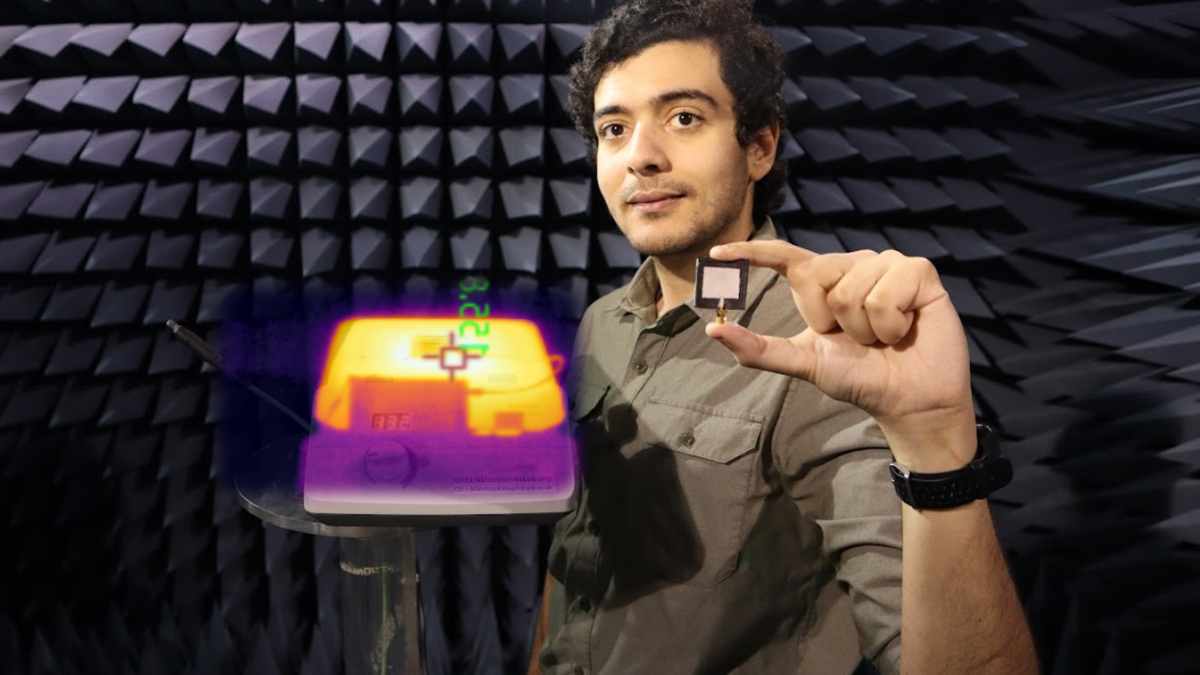

Led by Dr. Mahmoud Wagih, the team designed a versatile composite using common silicone and carbon fibers, allowing it to be easily shaped into various forms. These skin-like substrates can function as large-area antennas, emitting signals highly sensitive to temperature changes. Unlike traditional thermistors limited to narrow temperature ranges, this novel sensor can read temperatures across an extensive span from 30°C to over 200°C.

Published in Nature Communications, the research details the use of a 3D printer to mold the flexible material and integrate it into components such as antennas, RFID labels, and resonators. The sensor’s ability to absorb radio-frequency radiation at temperatures up to 300°C was rigorously tested, showcasing its resilience and adaptability.

This advancement not only expands the temperature sensing range but also holds promise for reducing costs and enhancing sustainability in wireless sensor technology. By requiring fewer devices to cover the same temperature range, the new soft, flexible temperature sensor demonstrates potential for economic and ecological benefits.

Collaborating with researchers from the Universities of Southampton and Loughborough, as well as PragmatIC Semiconductor Ltd in Cambridge, the project received support from the UK Engineering and Physical Sciences Research Council (EPSRC), the Royal Society, and the Royal Academy of Engineering, along with the Office of the Chief Science Adviser for National Security.

You can read the full research paper, titled “Wide-range soft anisotropic thermistor with a direct wireless radio frequency interface” at this link.

Come and let us know your thoughts on our Facebook, X, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.