Researchers at the University of Stuttgart have successfully integrated 3D printed micro-optics with fiber optics to create a new hybrid laser system. This innovation, detailed in the Optica Publishing Group’s journal Optics Letters, represents a significant advancement in laser technology, combining the attributes of fiber-based and solid-state lasers.

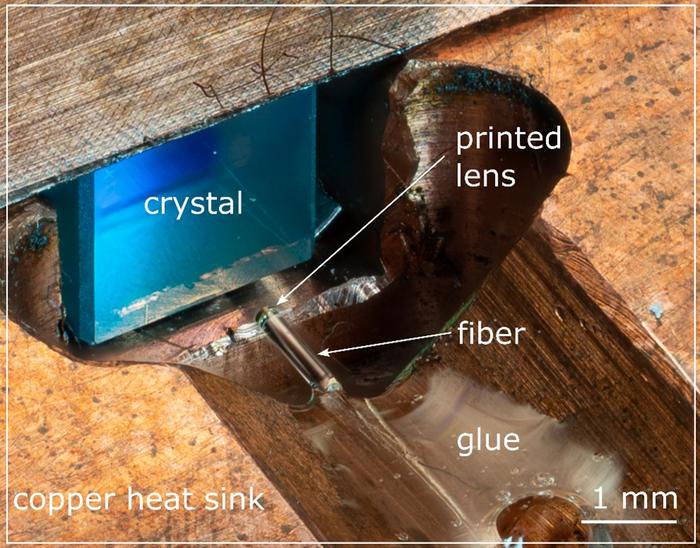

The team, led by Simon Angstenberger, utilized two-photon polymerization 3D printing to affix microscale lenses onto optical fibers, enabling a more compact and stable laser oscillator design.

This development marks the first instance of 3D printed polymer-based micro-optics being used in high-power applications, demonstrating their ability to withstand the heat and power levels inside a laser. The hybrid laser achieved stable operation at over 20 mW with a peak output of 37 mW at 1063.4 nm. These 3D printed optics, previously limited to low-power applications, now show promise for high-power uses in fields like lithography, laser marking, and medical applications.

The process involves focusing an infrared laser into a UV-sensitive photoresist, allowing for the creation of intricate shapes and free-form optics. Surprisingly, these polymer-based lenses exhibited remarkable stability under significant heat and optical power, with no visible damage after extensive use.

Future endeavors include optimizing the efficiency of these printed optics and experimenting with different crystals to customize the laser’s output for specific applications. The successful implementation of 3D printed micro-optics in a high-power laser context opens new possibilities for compact, robust, and cost-effective laser sources.

You can read the full paper, titled “Hybrid Fiber-Solid State Laser with 3D-Printed Intracavity Lenses” at this link.

Come and let us know your thoughts on our Facebook, X, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.