Researchers at Fraunhofer have developed a 3D printed adhesive, harnessing the properties of dihydroxyphenylalanine (DOPA), to improve the lifespan of medical implants like hip prostheses. The adhesive, inspired by the mussel’s natural bonding ability, combines DOPA with apatite, a ceramic found in bones and teeth.

This development addresses a critical issue in hip replacement surgeries: the body’s tendency to reject titanium implants. By facilitating a stronger bond between bone and titanium, this approach could significantly reduce the need for multiple surgeries, particularly in younger patients.

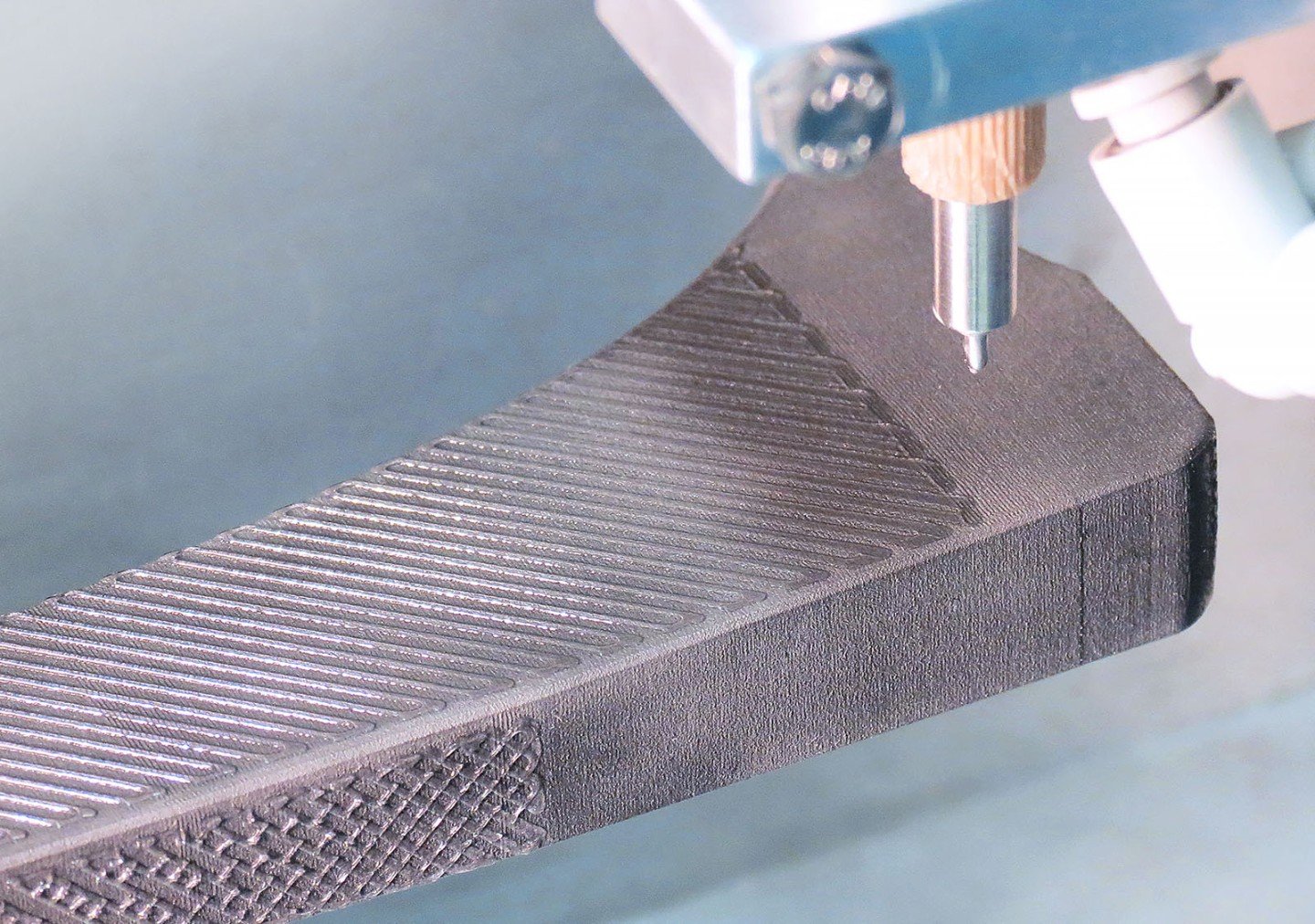

The concept of using DOPA for adhesion is not new, but its application in 3D printing, especially for creating custom shapes that fit individual anatomical needs, marks a substantial advancement. Traditional titanium castings are limited in size and shape, but 3D printing allows for precise customization, which is crucial for matching complex geometries found in the human body. This technology can adapt to various scenarios, such as reconstructing bones shattered in accidents, thereby increasing the contact area and ensuring a more secure and long-lasting fit for hip replacements.

The potential of this project extends beyond hip implants. It aligns with ongoing research in fields like Bioglass, which focus on treating dental diseases and promoting bone growth around implants. With further research and regulatory approvals, this adhesive could significantly enhance the quality of life for individuals with joint issues due to age or injury.

Come and let us know your thoughts on our Facebook, X, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.