In a recent development, MIT researchers have utilized additive manufacturing to craft a miniaturized quadrupole, a key component of mass spectrometers. This 3D printed device is not only cost-effective and lightweight but rivals commercial-grade filters in terms of precision.

Mass spectrometers play a pivotal role in various applications, from crime scene analysis to environmental monitoring. However, their traditional counterparts are bulky, expensive, and challenging to deploy effectively. Enter MIT’s innovative approach: a 3D printed quadrupole that could revolutionize the core of mass spectrometry.

The miniaturized quadrupole, fabricated from durable and heat-resistant glass-ceramic resin, marks a significant leap in portable mass spectrometry. Unlike conventional filters, this 3D printed component requires no assembly, eliminating performance-hampering defects. Its compact design, costing only a few dollars, competes with commercial-grade counterparts exceeding $100,000, heralding a new era in accessibility.

MIT’s development extends the applications of mass spectrometry beyond traditional confines, and could be deployed to areas such as remote rainforest areas, for swiftly analyzing potential pollutants on-site. Additionally, its lightweight nature makes it an ideal candidate for space missions, monitoring chemicals in Earth’s atmosphere or distant planets.

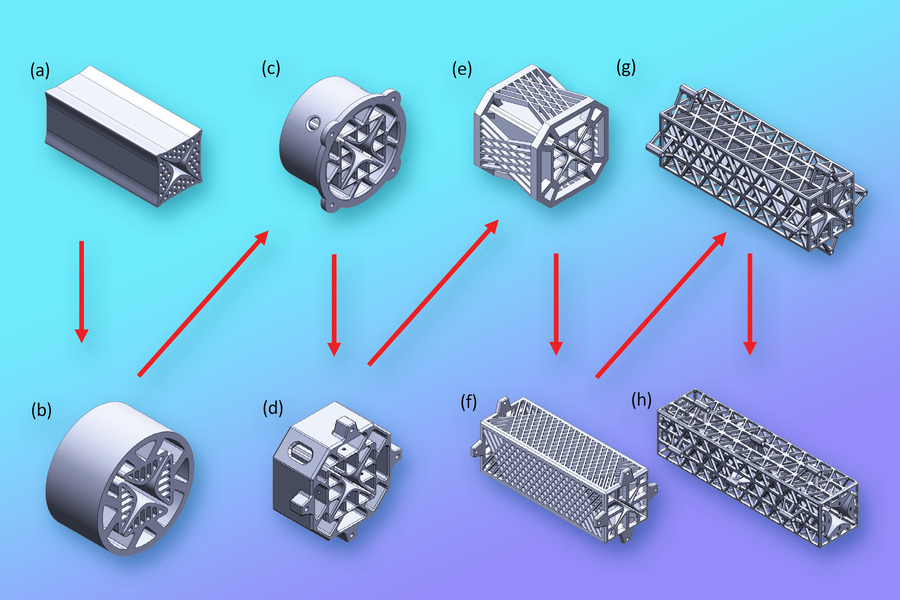

The researchers have leveraged a glass-ceramic resin that withstands high temperatures, employing vat photopolymerization for precise 3D printing of the part. The resulting hyperbolic rod design, challenging to achieve conventionally, enhances mass filtering efficiency.

To maximize performance, the team employed electroless plating to coat the rods with a thin metal film, ensuring electrical conductivity. Tests have demonstrated that the 3D printed quadrupoles outperform their stainless-steel counterparts in resolution and precision.

“We are not the first ones to try to do this. But we are the first ones who succeeded at doing this,” said Velásquez-García, senior author of a paper detailing the project.

“There are other miniaturized quadrupole filters, but they are not comparable with professional-grade mass filters. There are a lot of possibilities for this hardware if the size and cost could be smaller without adversely affecting the performance”.

As the researchers plan to enhance quadrupole performance by increasing length and exploring alternative ceramic materials, the future holds promise for more precise and versatile 3D printed mass spectrometry solutions. This breakthrough not only transforms the landscape of chemical analysis but opens avenues for cost-effective, portable spectrometry in diverse environments.

The research paper, titled “Low-Cost, Compact Quadrupole Mass Filters with Unity Mass Resolution via Ceramic Resin Vat Photopolymerization” can be found in Advanced Science at this link.

Come and let us know your thoughts on our Facebook, X, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.