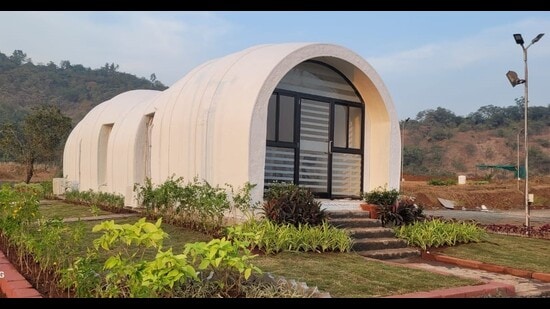

Godrej Construction, a subsidiary of Godrej & Boyce, has leveraged 3D Construction Printing to complete ‘The Cocoon,’ a 500 sq ft office, in “just 40 hours”. At a campus in Khalapur.

The Cocoon, distinguished by its curved elliptical design, utilized prefabricated modules created through 3D Construction Printing (3DCP) technology. Lean construction methods, Building Information Modelling (BIM), and sustainable practices, including 20% recycled concrete aggregates, were integral to the project’s success.

Anup Mathew, Senior Vice President at Godrej Construction, highlighted the project’s embodiment of pushing architectural and construction boundaries. The entire construction process, covering diverse elements from civil works to landscaping, was accomplished within the impressive timeframe.

Abhijeet Gawde, Head of Business Development & Marketing, emphasized the strategic use of 3D construction printing to accelerate timelines. The column-less structure with an elliptical design not only met the challenge but also showcased the technology’s capability to handle complex designs efficiently.

As the global landscape for 3D construction printing evolves, Godrej Construction’s pioneering efforts set the stage for future advancements. Their commitment to sustainability, exemplified by the use of recycled concrete aggregates, aligns with the imperative to reduce the construction sector’s carbon footprint.

According to the company, The Cocoon was installed with civil works, waterproofing, flooring, external and internal painting, electrical works, lighting, AC installation, plumbing, drainage and sanitation fixtures, office furniture, and landscaping all finished in under 40 hours.

Come and let us know your thoughts on our Facebook, X, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.