At Stanford University’s Congreve Lab, researchers Tracy H. Schloemer and Daniel N. Congreve are exploring the practical power of manipulating light’s color, with implications spanning from 3D printing to solar energy.

The key to their research lies in a process known as upconversion, which can transform low-energy photons into higher-energy ones. While this phenomenon has been studied for decades, recent advancements in materials and techniques have made it more practical. Schloemer and Congreve employ a method called triplet-triplet annihilation, using abundant materials and low-power lasers.

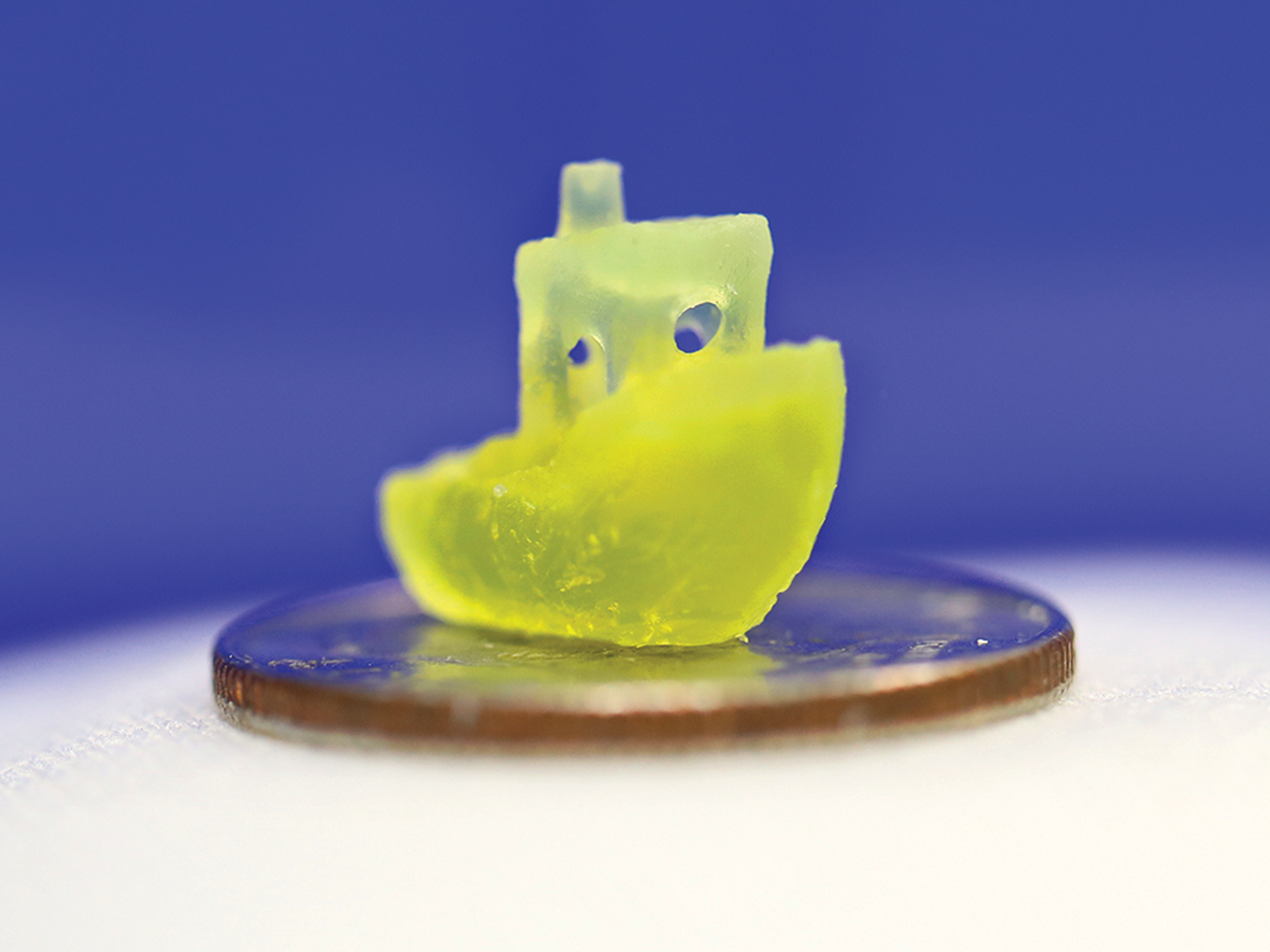

The research includes an innovative application of 3D printing. The team utilizes a process that changes the color of light, making it a valuable tool for precise additive manufacturing. In their approach, they disperse nanoparticles with sensitizers and annihilators in a resin. Instead of starting with blue or UV photons, which are traditionally used for curing resin in 3D printing, they use a red laser beam.

The crucial aspect of their 3D printing technique is the aforementioned phenomenon of upconversion, which occurs at specific light intensities. By focusing the red laser beam on a specific point within the resin pool, they increase its intensity, causing upconversion to create a small dot of blue light at the focal point. This blue light cures the resin at that spot. By moving the focal point, they can create intricate 3D objects within the resin pool. This entire process can be executed using a low-power laser, similar to a typical laser pointer.

Another application of their work is enhancing solar cell efficiency. Current single-junction solar cells only harness a fraction of available sunlight, limited by the mismatch between incident light colors and the cell’s energy bandgap. By upconverting low-energy photons into more useful high-energy ones, they aim to increase solar cell performance.

This new 3D printing method offers the potential for rapid and precise 3D printing at the nanoscale while avoiding the issue of breaking down the resin caused by high-powered lasers, opening up new possibilities for advanced 3D printing applications.

Source: spectrum.ieee.org

Come and let us know your thoughts on our Facebook, Twitter, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.