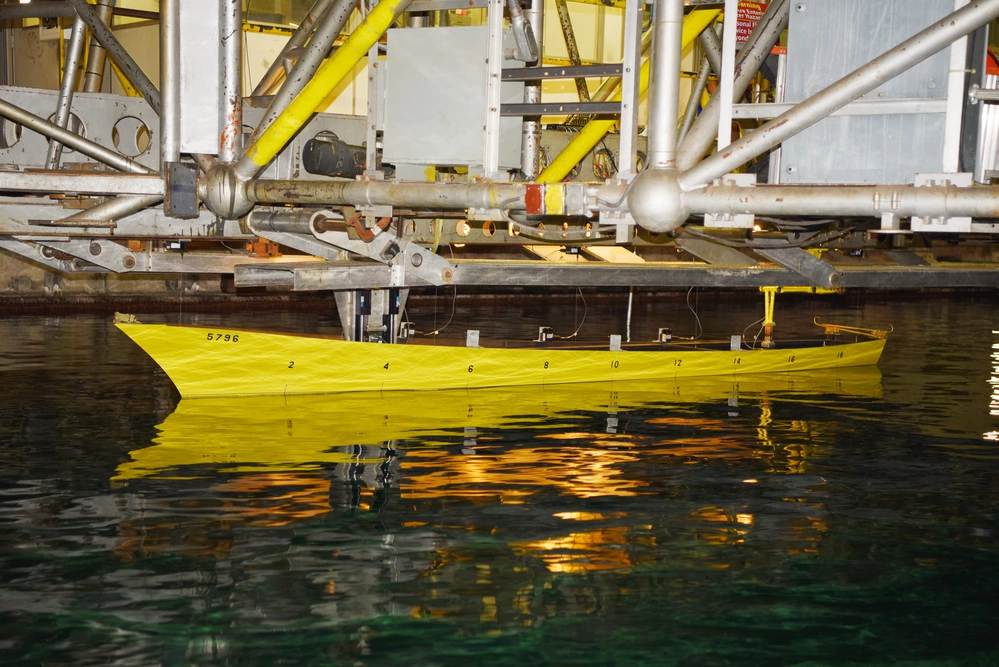

The Naval Surface Warfare Center is engaged in a study to evaluate the feasibility of using Large Scale Additive Manufacturing (LSAM) for naval model testing. This study, part of the LSAM FY 21-23 task proposal, aims to determine if 3D printed models can match the performance of traditional fiberglass models in resistance testing. The focus is on the David Taylor Model Basin (DTMB) where a model of the Arleigh-Burke class destroyer (DDG 51) was tested.

The initiative began as a concept in 2019-2020 with the successful 3D printing of a submarine bow model. This led to the creation of a full-size surface ship model, funded by the Naval Innovative Science and Engineering (NISE) program.

“I think one of the big interests within Carderock as a whole, and especially our department, is wanting to transition this technology for practical use,” said Engineer Kyle Mosqueda.

“We could build models a lot faster and a lot cheaper.”

The testing involved comparing the LSAM model with a fiberglass model in terms of water absorption, hull integrity, and deformation. The 3D printed model, produced by Airtech International, Inc., underwent calm water tow tank tests at speeds equivalent to 7 mph.

Preliminary results are promising, showing comparable performance between the LSAM and fiberglass models in resistance and deformation. This success has led to further funding for structural evaluation and future testing in simulated sea states.

“I’m curious to see if the DDG 51 model deflects while underway,” said Mosqueda.

“I am testing the fiberglass model and the LSAM model one after the other, and then comparing the results. I have high confidence that they will be comparable and will further validate this great piece of technology for future implementation.”

The successful implementation of LSAM in naval model testing could transform the industry’s approach to hydrodynamic research and design. This method promises enhanced efficiency in model production, potentially leading to more innovative designs and improved testing methodologies in naval engineering.

Source: dvidshub.net

Come and let us know your thoughts on our Facebook, X, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.