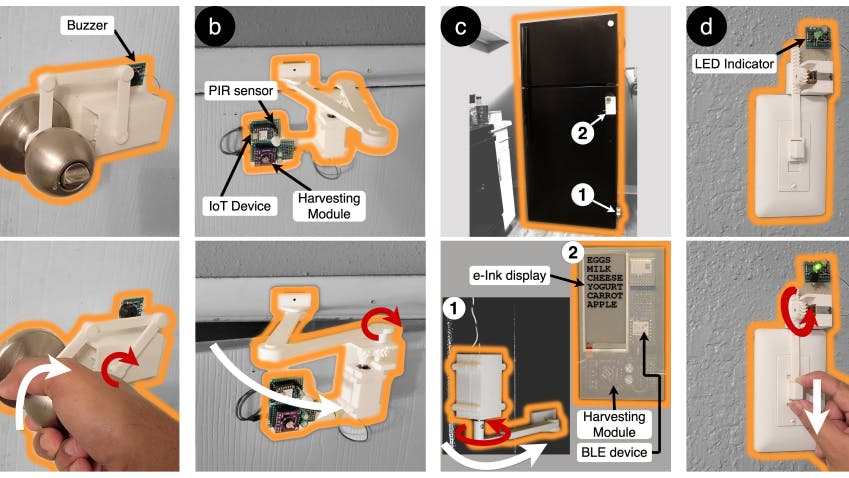

Smart sensors and IoT devices are pervasive but largely dependent on batteries, generating both financial and environmental costs. The E3D toolkit, developed by researchers at Texas A&M University and the University of California, Los Angeles, aims to mitigate this through 3D printable energy harvesters. Using inertial measurement unit (IMU) data from a smartwatch, the toolkit employs machine learning algorithms to identify suitable activities and objects for energy harvesting. The resultant data informs the design of a 3D model that can capture wasted energy to power a DC motor.

The toolkit streamlines the usually complex process of designing energy harvesting devices by obviating the need for interdisciplinary expertise. A web-based application with a Python back-end guides the user in fine-tuning the design, choosing the type of motion to be exploited, and confirming the object to which the device will be attached. The toolkit’s versatility allows for deployment in diverse environments, from industrial to domestic settings.

Energy harvesting solutions have long faced challenges of customization and complexity, but E3D offers a more accessible pathway. It leverages readily available technologies like 3D printers and off-the-shelf smartwatches, making the energy harvesting process customizable and cost-effective. While aesthetics are secondary to functionality at this stage, the toolkit’s modular approach to design significantly reduces barriers to entry.

In the future, toolkits like E3D could catalyze the widespread adoption of energy harvesting systems, potentially reducing our reliance on traditional batteries and their associated environmental impact.

Source: hackster.io

Come and let us know your thoughts on our Facebook, Twitter, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.