A collaborative study by RMIT University and the University of Melbourne has explored the impact of graphene oxide on 3D printed concrete. This research marks the first detailed examination of how graphene oxide, a nanomaterial prevalent in batteries and electronics, influences concrete’s printability and compressive properties. The findings reveal that incorporating graphene oxide not only enhances concrete’s electrical conductivity but also boosts its strength by up to 10%. The researchers emphasized the potential for creating ‘smart’ buildings with this concrete, where walls can serve as sensors for detecting minute cracks.

Traditional methods like ultrasonic or acoustic sensors, though effective for large crack detection, struggle with early identification of smaller fissures. The bulky equipment used for these methods presents challenges in monitoring vast structures such as bridges or skyscrapers. Graphene oxide’s inclusion, however, paves the way for an embedded electrical circuit within concrete structures, aiding in the early detection of structural issues and environmental changes.

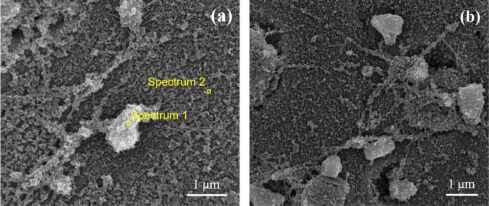

Graphene oxide’s promise extends beyond just smart applications. It could also enhance the practicality of 3D printed concrete in construction, offering benefits in cost and sustainability. The study highlights the labor, time, and waste reduction advantages of 3D printing over traditional formwork methods. Additionally, graphene oxide improves inter-layer bonding in 3D printed concrete, essential for structural integrity.

However, the research also underscores the delicate balance required in the concrete mixture. Excessive graphene oxide can disrupt the hydration process vital for concrete strength, leading to potential printability and durability issues. The next research phase will focus on the electrical conductivity of graphene oxide in concrete, further assessing its viability as a smart material.

You can read the research paper titled “Exploration of using graphene oxide for strength enhancement of 3D-printed cementitious mortar” in Additive Manufacturing Letters at this link.

Come and let us know your thoughts on our Facebook, X, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.