In a recent webinar, a Department of Defence official has expressed how 3D printing will aid hypersonic weapons production for the Pentagon.

Keith DeVries, DoD Manufacturing Technology Program Manager emphasized the pivotal role of AM in simplifying and expediting the defense manufacturing processes.

DeVries pinpointed the drastic reduction of welds, brazings, and joints as a major advantage, eliminating the necessity for extensive nondestructive testing, thus reducing production timelines.

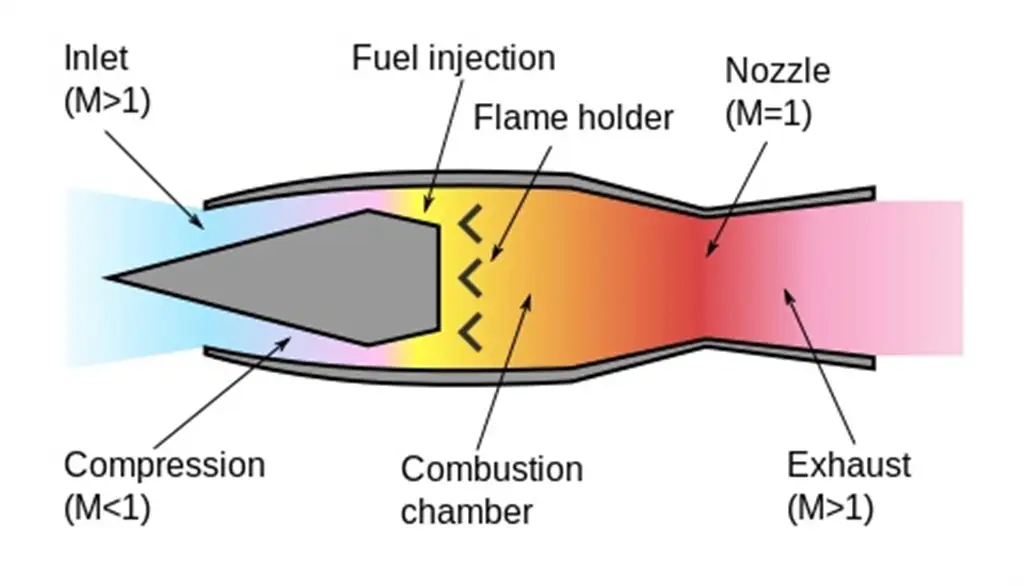

“The ability for additive to enter into those spaces is enabling some fantastic capabilities in our hypersonic weapons manufacturing, it’s a re-emerging requirement in our DOD space and the ability for additive to enable complex chambers in our scramjet propulsion is frankly a game changer,” he said.

“Additive manufacturing provides a shorter design loop for the changes that may be rolled into different hypersonic weapon systems.”

With AM already being incorporated within the defense manufacturing base, notable through programs like Additive Manufacturing Now with the Army, the demonstrated success in producing over 2,000 military parts showcases the enormous potential of AM.

The adoption of this technology, according to DeVries, is an unequivocal advancement, bridging the gap between complex designs and their manifestation into cutting-edge hypersonic weaponry.

Come and let us know your thoughts on our Facebook, Twitter, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.