Recent advancements in bioprinting open possibilities for repairing organ damage by cultivating replacements in labs. A key challenge is accurately bioprinting live cells into 3D structures that mimic biological tissues. Osaka University researchers, in a study published in ACS Biomaterials Science and Engineering, have made strides in this domain, overcoming previous barriers to geometrical fidelity and cell growth.

Bioprinting involves the layer-by-layer assembly of tissues by ejecting cell-laden ink to form 3D structures. Soft structures, while challenging to print, are optimal for cell growth. Prior challenges included unwanted contamination during ink solidification. The study aimed at ink solidification into a soft matrix without contamination while maintaining cell viability.

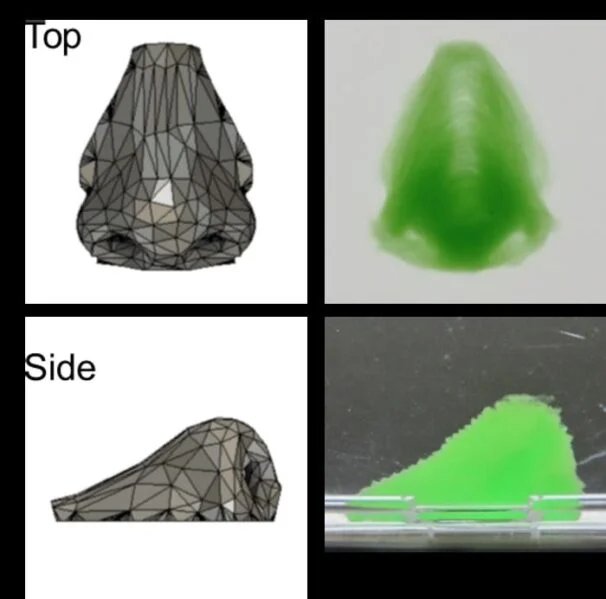

“In our approach, a 3D printer alternately dispenses the cell-containing ink and a printing support,” said Takashi Kotani, lead author of the study.

“The interesting point is that the support also plays a role in facilitating the solidification of the ink. All that’s necessary for ink solidification is in the support, and after removing the support, the geometry of the soft printed cell structures remains intact.”

A unique aspect of this research was the use of hydrogen peroxide from the support to initiate gelation, yielding a gel-encased cell assembly in mere seconds, thus preventing contamination.

Senior author Shinji Sakai stated that mouse fibroblast cells maintained their geometry and growth, emphasizing the potential in tissue engineering. The study suggests potential advancements in regenerative medicine and pharmaceutical toxicology.

Looking ahead, refining this bioprinting technique can lead to improved human cell assemblies and tissues, and potentially bring bioprinted models closer to mimicking biological tissue and organs. Further work could also involve further optimizing the ink and support, as well as incorporating blood vessels into the artificial tissue.

You can read the full research paper, titled “Horseradish Peroxidase-Mediated Bioprinting via Bioink Gelation by Alternately Extruded Support Material” at this link.

Source: scienceblog.com

Come and let us know your thoughts on our Facebook, Twitter, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.