Edurne Heredia had a distinct spinal issue: a triangular lumbar vertebra, resulting from congenital scoliosis. This abnormality impacted her daily activities, causing discomfort in her hips, knees, and overall body. Working as a customer service representative involved physical tasks, which exacerbated her pain.

Dr. Herdeep Singh from UConn Health’s Comprehensive Spine Center identified this as a congenital hemi-vertebra. Typically, vertebral alignment is maintained by disks between them. However, a hemi-vertebra disrupts this balance, causing the spine to lean. Over time, this can lead to increased degeneration, causing more pain and affecting routine activities. Heredia had explored various treatment options, including medications and injections, but her condition only worsened.

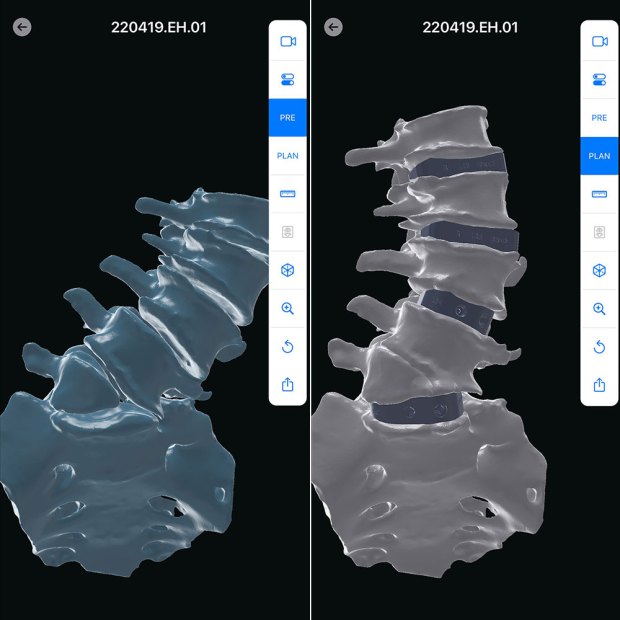

Traditional solutions involve using off-the-shelf implants. However, these aren’t tailored to individual patients. Singh’s approach was different. Leveraging CT scans and MRIs, his team collaborated with Carlsmed, a California-based company, to design custom-made spacers for Heredia. The software mapped the spine’s surface, enabling the creation of implants that perfectly fit the bone’s topography.

After the successful surgical implantation of these spacers, Heredia experienced significant improvement. Though recovery is estimated at 18 months, her posture and pain levels have notably enhanced. An additional benefit was a slight increase in her height. While Heredia’s spine may never achieve complete straightness, the improvement is substantial, underscoring the potential of 3D printing in medical applications.

In light of these advancements, the 3D printing industry may see increased collaboration with the medical sector, offering more personalized solutions for intricate challenges.

Source: courant.com