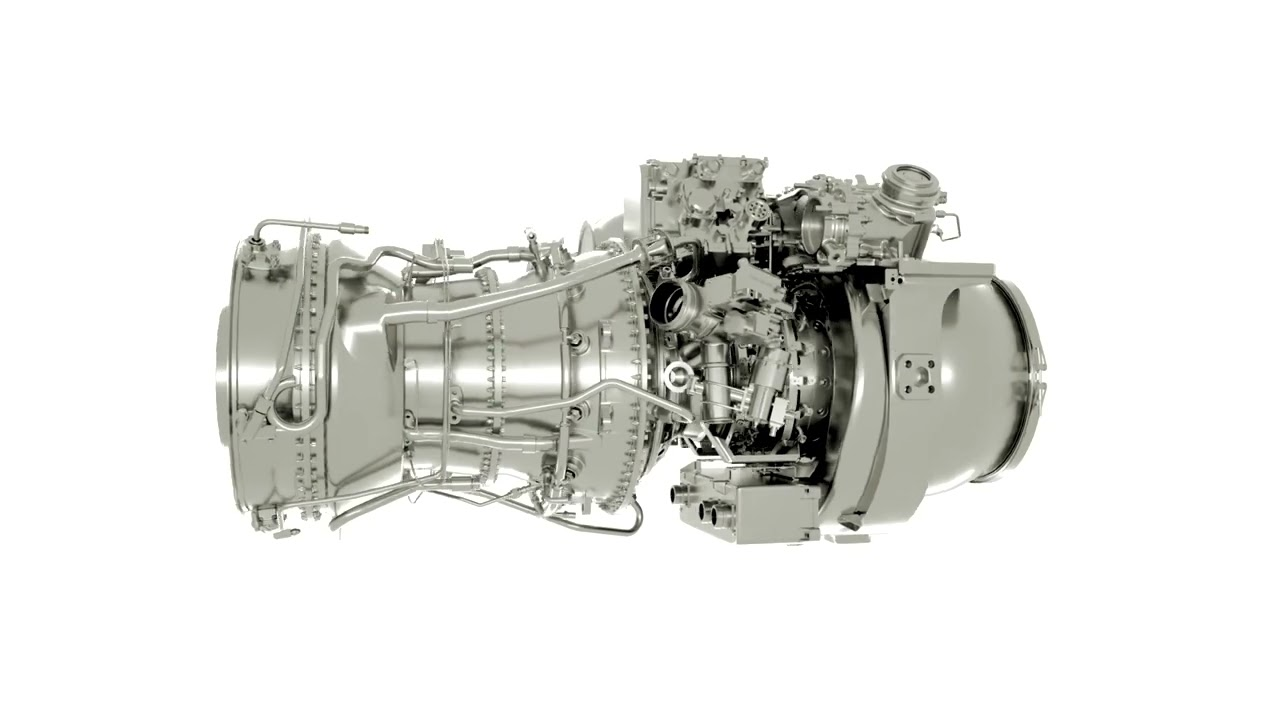

GE Aerospace has received US Army approval for flight testing its T901-GE-900 engines, incorporating metal additive manufacturing components. Designed for use in UH-60 Black Hawk, AH-64 Apache, and Future Attack Reconnaissance Aircraft (FARA) helicopters, these engines represent an advancement in the utilization of AM for aerospace applications. Official acceptance occurred at GE’s Lynn, Massachusetts facility by the Defense Contract Management Agency.

The T901 engine incorporates metal AM technologies, 3D modeling, and ceramic matrix composites (CMCs). These elements contribute to an increased power output and a reduction in weight, two pivotal factors in rotorcraft performance. The T901 also shows a 50% rise in power over its predecessor, the T700 engine, while reducing life cycle costs due to its streamlined design and fewer mechanical parts.

Fuel efficiency improvements are another notable attribute. The new engine configuration will extend the fleet’s operational range and reduce fuel consumption rates, a factor directly impacting operational logistics and sustainment costs.

A modular design approach, inherited from the T700, aids in the T901’s easy integration with existing US Army helicopter systems. This modularity enhances the engine’s reliability, maintainability, and further diminishes life-cycle expenses.

The acceptance of the T901 engine with AM components indicates an increasing reliance on additive manufacturing techniques for critical aerospace applications. This could well prompt accelerated research and implementation of AM in other military and civilian aerospace sectors.

Come and let us know your thoughts on our Facebook, Twitter, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.