Researchers from Texas A&M University have created a new class of 3D printable inks that are not only conductive, but are also extremely biocompatible as well. This technology could help develop the next generation of wearable and implantable biomedical devices, and could offer those engineers a new tool in their tool belt.

Flexible electronics have been around for decades now and the biomedical field has had a large interest in them since their conception. Their flexible wiring and biocompatibility are an ideal combination for a variety of devices ranging from sweat receptors to nerve cuffs and everything in between. However, when designing these types of devices there has often been a trade off between conductivity and biocompatibility. Neither extreme is ideal, and something needed to change in order to widen the capabilities of biomedical devices.

Enter Texas A&M.

The team from the Gaharwar Laboratory also saw this void in the research and wanted to try their hand at finding a solution that gave scientist the best of both worlds.

Their solution? 3D printed and conductive bio-inks.

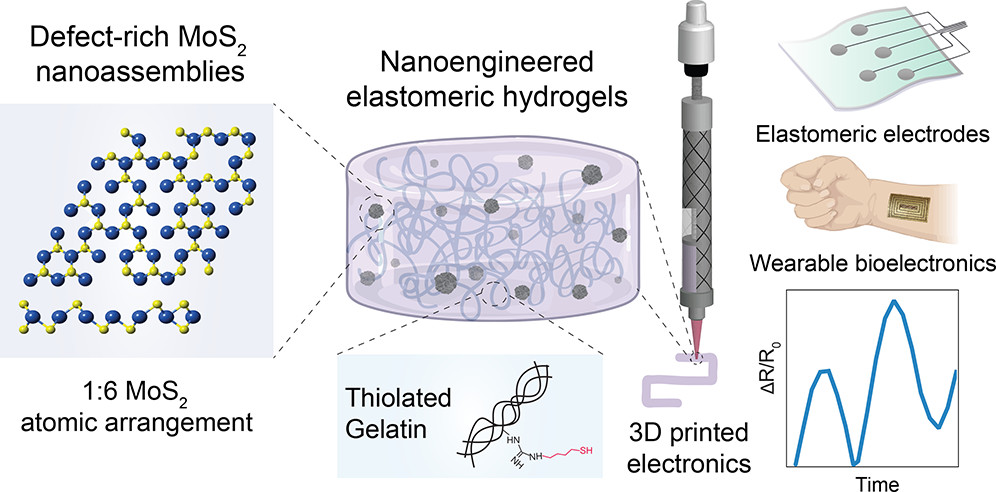

The research group had a background in bio 3D printing and ultimately leveraged a new class of 2D materials, molybdenum disulfide (MoS2), to include in their hydrogel ink. The new nanomaterial acts as a defect center in the ink and allows for easy electrical conduction when printed. The group also took advantage of the ink’s shear-thinning properties that allows the composition to act as a solid inside the tube and as a liquid when extruded. This helped print the crosslinked ink, and the resulting material was mechanically robust and could bend, twist, and compress without damaging the device.

So far, they have been able to print complex 3D circuits and electronic devices not possible via traditional manufacturing techniques, and even see its potential as an electronic tattoo to monitor Parkinson’s patient’s movements.

The 3D printed devices were printed using open source software and a multi-head 3D bioprinter. Their process is fully customizable and open which will help scientists from all around the world expand on this research.

While this is a newer technique, this is an exciting breakthrough for bioprinting. For a long time, there’s been a trade off between choosing a conductive bioelectronic device or a mechanically biocompatible device, and now that is no longer the case with this ink. The new ink now offers the best of both worlds and fills a much needed hole in the biomedical research space. So far this ink looks promising, and if it continues to improve from here, it could end up being a cornerstone for wearable electronics well into the future.