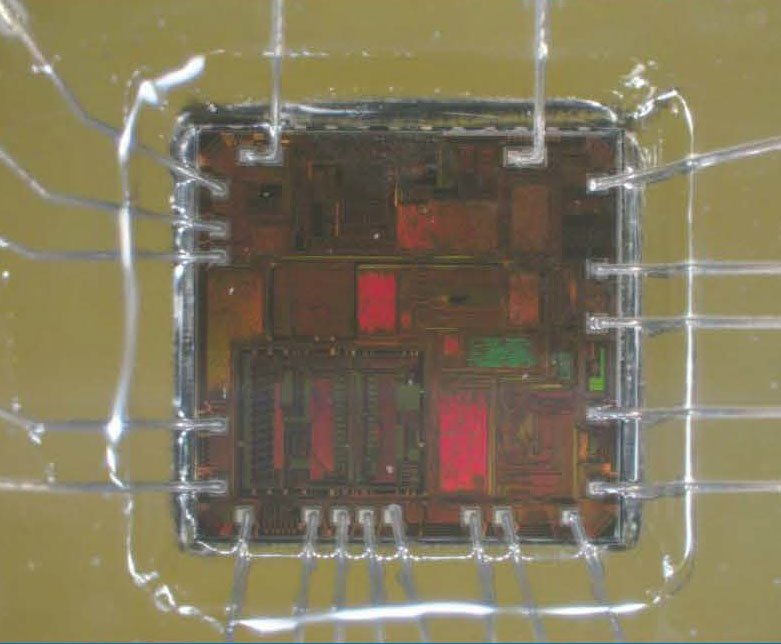

Optomec has announced the release of their proprietary software, KEWB, specifically designed for high volume production of 3D printed electronics. Built on the experience of 400 installed Aerosol Jet industrial printers, KEWB targets high volume production customers working with applications like multi-chip packaging, mm-wave interconnects, heterogeneous chip integration, and 3D printed antennas for 5G devices.

KEWB is offering enhanced operator guidance, powerful vision and alignment tools, extended runtime process control, and industry 4.0 connectivity to satisfy the requirements of manufacturers. Its powerful scripting capability will enable the automated sequencing of critical process steps for continuous inline production, such as loading, scanning, aligning, printing, inspecting, and unloading.

The software’s release comes after the introduction of the Aerosol Jet HD2 printer, a high-precision printed electronics and material dispensing platform that combines high-speed, sub-micron resolution, SEMI-compliant inline conveying, and advanced alignment optics over a 300 x 300 mm work area.

“The new KEWB software simplifies everything — from process integration to operation sequencing to maintenance.” said Dave Gleason, Software Development Manager at Optomec.

“In addition, it’s configurable for multiple user levels, so the engineer sees a full vision tool kit while the machine operator sees a simplified, pictorial sequence of process steps. The entire software approach is focused on production.”

KEWB streamlines process integration, operation sequencing, and maintenance, focusing entirely on production, and the Optomec printers are used widely in the aerospace and defense, energy, medical device, advanced electronics packaging and research domains.

Come and let us know your thoughts on our Facebook, Twitter, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.