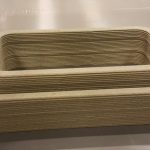

Engineers in Eindhoven the Netherlands are using a 3D printer that prints concrete to build the world’s first 3D printed concrete bicycle bridge. The bridge will be 8 meters long using over 800 layers of concrete and mortar.

The university is building the bridge in the city of Gemert. The bridge is located next to the Lady of Gemert statue, a local landmark. Since bridges serve a load-bearing purpose, many have voiced skepticism that the 3D printed construction will be durable. The team have assured everyone that it will be fully functional. The researchers have also tested the bridge using a scale model simulation.

The Growing 3D Printing Market in Construction

The increasing adoption of 3D printing in construction is unsurprising. Thanks to modern techniques the bridge did not require intense preparation or heavy scaffolding for workers to walk on. Additionally, it’s less labour-intensive for workers, allowing them to take on the job while sitting. Another benefit of this method was cheap and sustainable materials. Lower material costs can often reduce the cost of investment for robotics and other machinery.

Despite its advantages, many experts fear that 3D printing may put laborers out work. The engineers do not consider this technology a significant threat to construction workers. They share the opinion that since the robots still require someone to operate them, workers should be retrained, not given the pink slip. This retraining effort could help offset the problems caused by mechanisation.

Workers would now have significantly different duties in operating the robotics. This would include making the cement mixtures that the machines require, programming them and prepping them for building. While some jobs would become redundant, it does not mean that other opportunities do not open up. Overall, the team at TU Eindhoven are optimistic about the future of this technology.