MIT engineers have developed a breakthrough in the field of bioelectronic implants by creating a soft, metal-free electrode that mimics the properties of biological tissue. Traditional implants incorporate rigid metal electrodes, which can cause tissue damage and degrade performance over time. The new material, a high-performance conducting polymer hydrogel, can conduct electricity like conventional metals and is printable, allowing for flexible and customizable electrode designs.

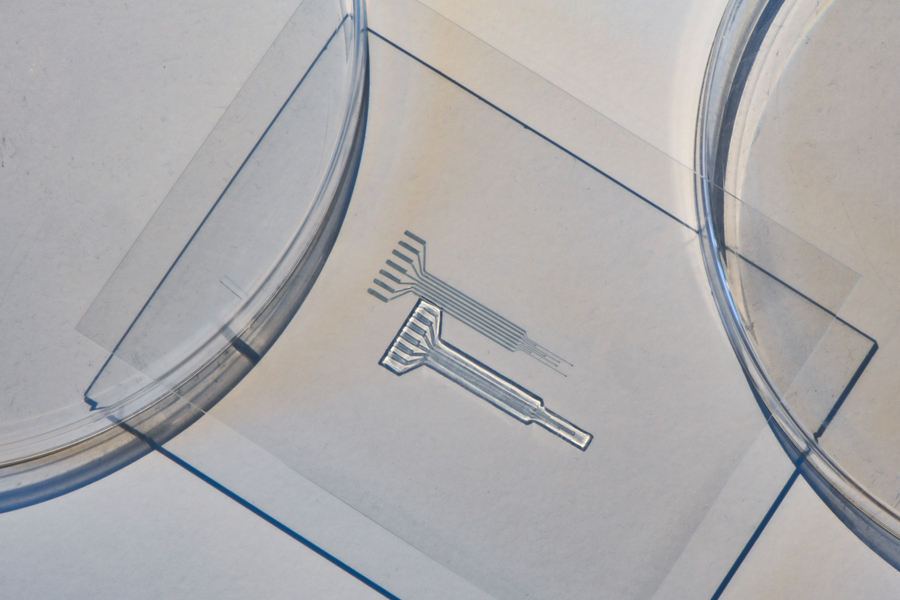

The researchers achieved this advancement by mixing conductive polymers with hydrogels in a way that enhances both their electrical and mechanical properties. By slightly separating the ingredients, they were able to create continuous strands of conductive polymers for electrical transmission and tough, stretchy hydrogel for mechanical support. The resulting gel was 3D printable and could be patterned onto films of pure hydrogel, resembling conventional metal electrodes.

In animal testing, the gel-based electrodes demonstrated excellent electrical and mechanical performance when implanted on the heart, sciatic nerve, and spinal cord of rats. They remained stable for up to two months with minimal tissue inflammation or scarring. The electrodes successfully relayed electrical pulses and stimulated motor activity in associated muscles and limbs.

The researchers believe the gel-based electrodes could have immediate applications in supporting patients recovering from heart surgery. By replacing metal electrodes with the soft gel, complications and side effects could be minimized. Additionally, the material has the potential for use in long-term implants like pacemakers and deep-brain stimulators.

“We believe that for the first time, we have a tough, robust, Jell-O-like electrode that can potentially replace metal to stimulate nerves and interface with the heart, brain, and other organs in the body,” said Xuanhe Zhao, professor of mechanical engineering and of civil and environmental engineering at MIT.

The team is continuing to improve the material’s longevity and performance to enable its use as a soft electrical interface between organs and implants. Ultimately, their goal is to replace conventional materials inside the body with biocompatible alternatives that offer improved performance and durability.

This research, supported by the National Institutes of Health, paves the way for safer and more effective bioelectronic implants that can restore functionality and improve the lives of individuals with various medical conditions.

Come and let us know your thoughts on our Facebook, Twitter, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.