L3Harris Technologies is partnering with Embry Riddle Aeronautical University to test 3D printed materials for use in satellites on the International Space Station (ISS).

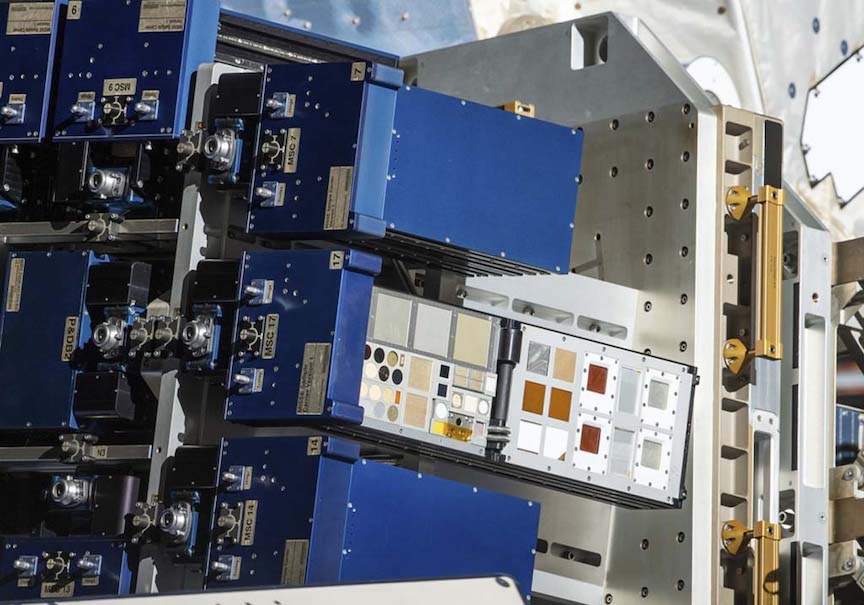

The payloads will be launched on SpaceX’s 27th Commercial Resupply Services mission, which includes a project to test L3Harris-designed 3D printed radio frequency (RF) circuits and various 3D printed material samples.

The materials will be subjected to extreme temperatures, radiation and atomic oxygen to validate their performance in low Earth orbit (LEO) and to ensure they can withstand the harsh space environment. The project is a continuation of a 2021 experiment on the ISS that collected two months of data, and this time photonic material will also be tested for a new technology called photonic integrated circuits.

“We’re excited to test the 3D printed materials for six months and compare the new results with previous ISS experiments and ground tests,” said Arthur C. Paolella, senior scientist and technical fellow with L3Harris.

“The ability to 3D print materials for use in space opens up new possibilities for satellite design and construction while making spacecraft manufacturing more cost-effective and efficient.”

The results of the experiment will be used to develop and refine materials for use in satellite manufacturing, potentially reducing the size, weight, and power of communications systems and increasing the amount of data that can be transmitted from satellite to satellite.

L3Harris also plans to explore other potential space-based applications for 3D printed materials, such as in-orbit manufacturing and repair.

Come and let us know your thoughts on our Facebook, Twitter, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.