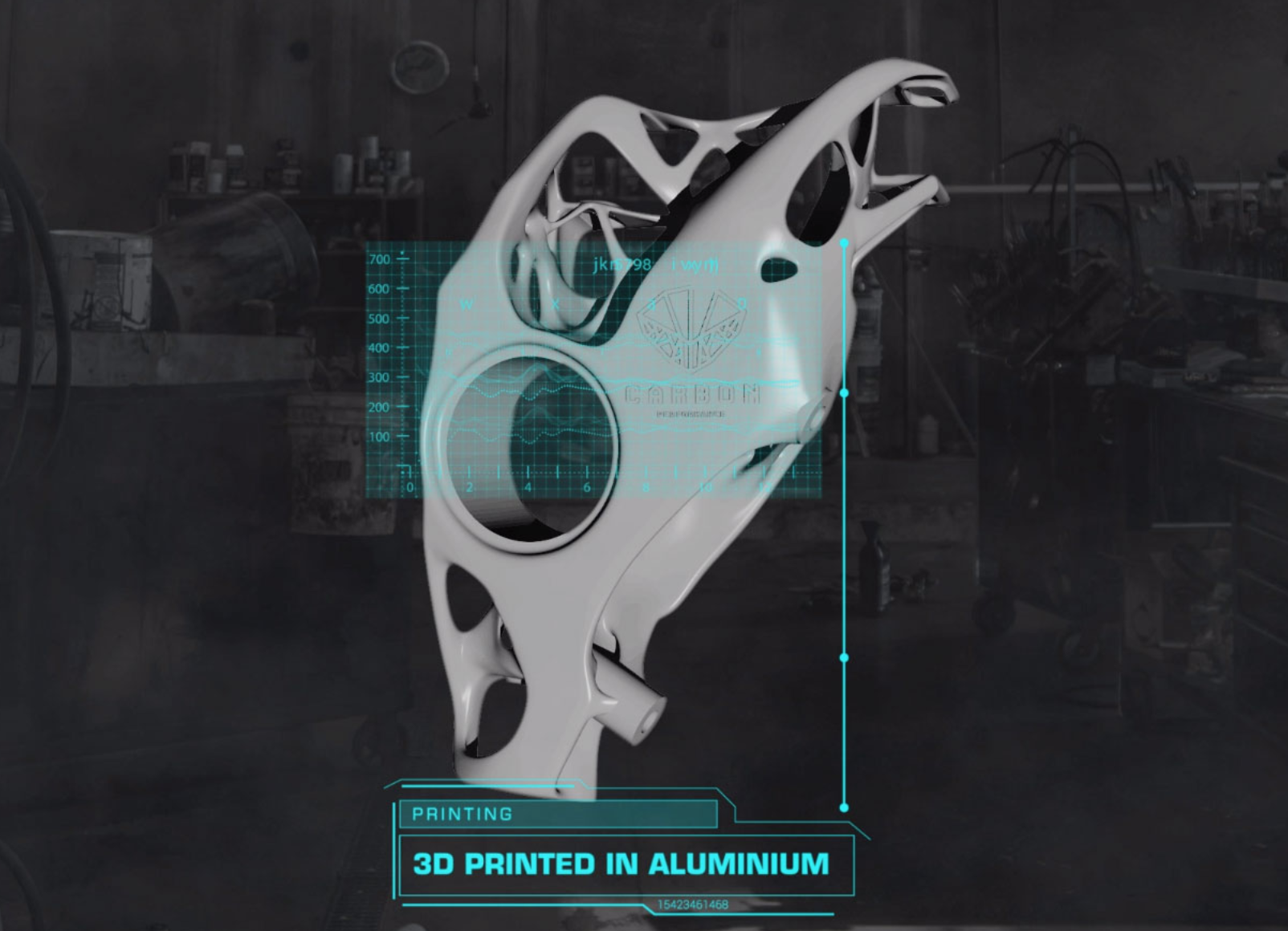

Carbon Performance, a British additive manufacturing company that serves the automotive industry, developed a set of 3D printed brake calipers that were designed using their new proprietary automated intelligent platform, SK3L370N. The platform generates the most environmentally sustainable geometry that also meets all the required design specifications, creating parts that are as light as possible.

The self-taught algorithms of SK3L370N optimize strength-to-weight ratios of geometries by automatically running cycles of generative designs and analysis; material is successively removed from the model up until it no longer meets specific stiffness requirements, and whichever iteration that uses the least amount of material without crossing the stiffness threshold is selected as the ideal geometry. Weight reduction of automotive parts generates value all along a product’s life, from lower manufacturing and shipping costs to increased performance/gas mileage for the end user due to their vehicle being lighter.

3D printing enables automotive manufacturers to consolidate multiple parts into one, such as when Carbon Performance made a single-piece 3D printed suspension upright for a Lotus that combined nine parts. Their new SK3L370N platform ensures that their consolidated assemblies are optimized for sustainability and performance. 3D printed assemblies can weigh 20% to 30% less than their counterparts, which could save automotive manufacturers hundreds of millions of dollars in materials and freight costs.

Gilbert Peters, CTO of Carbon Performance, explains, “Carbon Performance is truly democratizing the automotive industry making it accessible for automakers of all sizes from giants to independent start-up teams to develop the cars of tomorrow. I believe that it is the ripe time that the potential of additive manufacturing and digitalization is realized in the automotive and the wider transportation industry.”

Brake calipers are critical components of any vehicle as they provide the stopping power by gripping the brake rotor. Carbon Performance is making a bold strategic move by demonstrating their ability to improve a complex part that all vehicles use, and they’ve already created variations for cars from Tesla, Ferrari, Lotus, and Porsche.

Peters added, “The essence of mobility is changing quickly with electric autos growing at 59% and autonomous vehicles growing at 37%.” As such, they’ll be using the SK3L370N platform to design a completely 3D printed, autonomous electric car in 2020.