Electric motors are becoming very popular in the automotive world, with companies all around the globe vying for a slice of the EV pie.

And with such demand, comes innovation. Motors themselves haven’t changed much in design, fundamentally, since they were first invented, but advances in manufacturing of late have spurred motor designers to apply new methods in pursuit of performance gains and weight reduction.

We have seen a few examples of researchers and companies applying AM to electric motor production. One of the more visible examples is the 3D printed copper motor coil from German company Additive Drives.

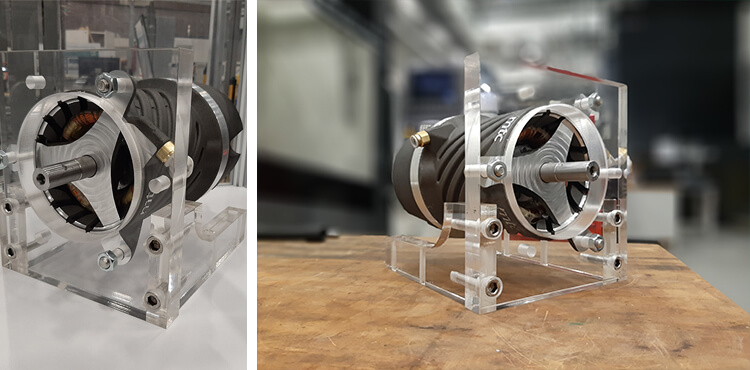

Researchers from the Manufacturing Technology Centre (MTC) in Coventry, UK, have recently been working on development of a motor with even more 3D printed components, in particular with 3D printed cooling systems.

Much of the project has been focused on developing workflows and assessing both the technical readiness level (TRL) as well as the manufacturing readiness level (MRL) of the project.

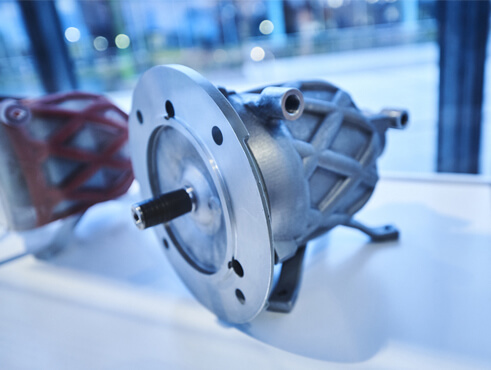

You can see one of the 3D printed motors in the image below. Note the fluid inlet/outlet and criss-crossed cooling channels in the casing.

By implementing liquid cooling channels into the motor casing, the motor was shown to produce more power without overheating, and benefit from a weight saving of 10%, and size reduction of 30%.

“The development of electric motors has not seen this level of focus for nearly 100 years despite being high on the priority list for many industry sectors that are seeking significant improvements in cost, quality, reliability and performance, in both gravimetric and volumetric terms,” said Steve Nesbitt, Chief Technologist at MTC.

“Systems engineering and integration – doing more with key components and materials – are key to achieving this and so additive manufacturing is a key enabler for developing complex features and forms, essential to improving the functionality and performance of electric motors, with singular and multi-materials solutions.”

The process of manufacturing electric motors has a number of challenges to overcome; complex or manual assembly, materials that are difficult to process and can be rare and/or expensive, thermal management and lightweighting.

The printed motor casing project has demonstrated a number of benefits including, increased motor power density, reduced part count, increased manufacturing efficiency and reduced lead times, lower running costs and waste reduction. Whew!

In short, the results so far have enabled MTC and their colleagues to develop a roadmap and examine the DfM/DfA for the development of 3D printed motors and have identified areas of research that should be focused on.

You can read more about what the MTC are doing over at this link.