Companies offering additive manufacturing files of their wares for customers to print is nothing new. Most of these digital items do however tend to be very niche products, designed for certain tastes, or for very specific products.

In order to enable a little more creativity and freedom (with fewer headaches) as far as these files are concerned, automaker Ford has recently announced that they are releasing CAD models, not of functional parts, but of part interfaces.

The interfaces can be printed and mounted to something like a “hardpoint” (a slot) on the Ford Maverick, and customers can print whatever they want and mount it to the interface.

But why?

Because designing things to fit onto other things that you haven’t designed yourself is a chore at the best of times, even with the right meteorological tools. Add the complicated curved surfaces of a modern car plastic interior to that equation, and without a 3D scanner, your part is likely going to be mating with your car interior very badly, with lots of gaps and whatnot.

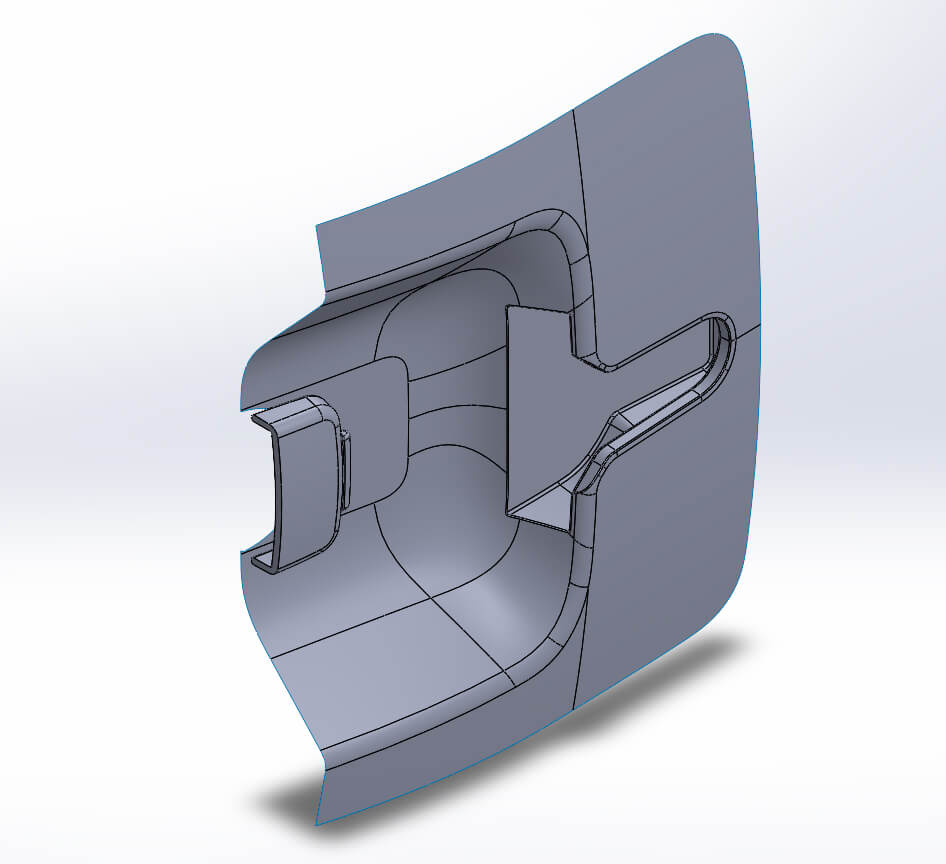

The Ford Integrated Tether System (F.I.T.S) is basically a bunch of slots molded into the hard plastic surfaces in the Ford Maverick. The slots are located in the center console and behind the seats. You can see the slot in the photo below.

As you can see in the CAD model below, the file provided by Ford is actually of the female slot itself, and it is for the customer to make a negative in their chosen CAD software, and then integrate their own widgets into the resulting male component. You can imagine it would be a bit time consuming to model this part without a drawing.

Ford suggests various accessory holders such as drinks holders and for electronic devices to get you started, but now that you have that sweet complicated curved CAD geometry, you can let your mind run wild safe in the knowledge that your printed parts will not only fit, it will fit as though it were designed by a Ford engineer themselves. Because it was.

Ford is already an old hand at 3D printed parts. In the past they have utilized AM in the production of 3D printed brakes for the Shelby Mustang, as well as teaming up with HP for the recycling of printed waste into new molded parts.

If you want to read more about the Ford F.I.T.S goodies, then you can read more about how to do it and what it is in more detail, as well as download a couple of CAD files, over at this link.

And for your information, the files are in .IGS, .STEP and .CATpart format. You’ll have to turn them into STLs for printing in your preferred CAD program or a capable slicer..