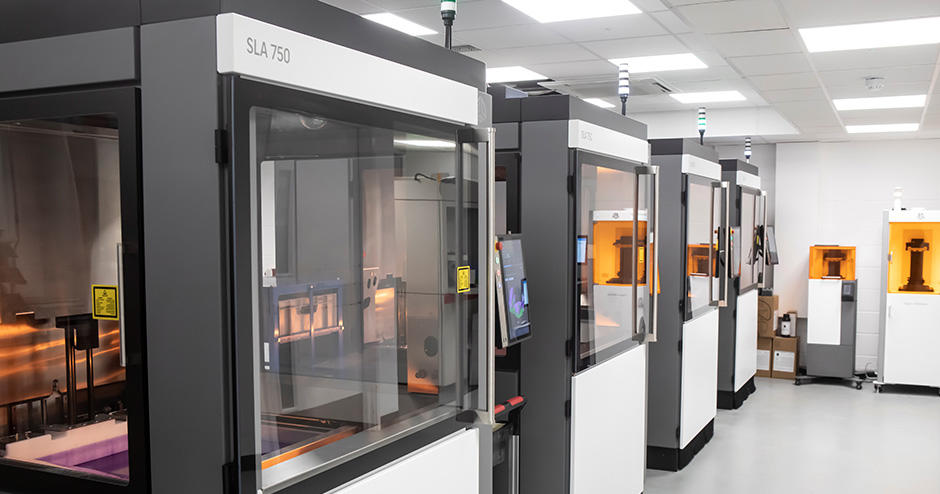

The BWT Alpine F1 Team has purchased four SLA 750 3D printing systems from 3D Systems to improve their additive manufacturing workflow. The team has been using the new 3D printers and the Accura Composite PIV material to produce models for wind tunnel testing.

The Accura Composite PIV material was co-developed by 3D Systems and BWT Alpine F1 Team has helped to produce more accurate, high-resolution data and take

The combination of printer and material has helped to improve performance, and produce unmatched sidewall and surface quality, high geometric accuracy, and excellent feature detail;. It has also significantly reduced the time taken to prepare from CAD to wind tunnel.

With the support of the SLA and SLS systems, the team has been able to produce 25,000 additively manufactured parts annually. The printers have enabled the team to maximize its wind tunnel investment and improve its understanding of the airflow over the car.

The SLA 750 is specifically designed to deliver the industry-leading combination of print size, speed, accuracy, and resolution for final parts that possess unmatched finish and mechanical performance, all of which are essential for aerodynamic test items.

The printer includes the 3D Sprint software, which is 3D Systems’ all-in-one software solution for preparing, optimizing, and printing 3D CAD data.

This is a significant move by the BWT Alpine F1 Team to accelerate innovation and speed to track. 3D Systems’ focus on building solutions that address customers’ application challenges has helped them advance the science of additive manufacturing and maintain their competitive advantage.

ome and let us know your thoughts on our Facebook, Twitter, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.