Two manufacturing giants, Airbus and Renishaw, have partnered on a new project to help build the next generation of aircraft wings with additive manufacturing.

The $23.15 million plan promises to be one of the most ambitious and innovative developments in aerospace design for many years. Both companies hope that the project will automate the production of aircraft wings, leading to a vast reduction in development time.

The manufacturing process for aircraft wings is notoriously tricky. According to Airbus Chief Operating Officer Tom Williams, “this project will look at ways we can increase the robustness of the design and test process while also reducing the time this takes”.

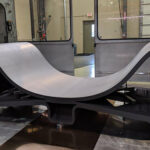

The project; codenamed WINDY, will examine the aerodynamic modelling of wings and how 3D printed components could be implemented in future designs. The inclusion of 3D printed components in aircraft wings could give a lighter, more efficient structure. This would be helpful as airlines move towards building aircraft with the environmental impacts in mind.

As anyone with a fleeting interest in 3D printing knows, the technology is exceptionally useful for saving time and making complicated tasks a lot simpler. Airbus have teamed up with Renishaw because the company is metal additive manufacturing. The precision measurements required for the design of aircraft wings makes Renishaw a valuable company to collaborate with.

More people fly now than ever before, and future passenger numbers are expected to keep rising due to competitive pricing by airlines vying for business. Numerous industry experts estimate that over 30,000 new aircraft will be required to meet customer demand over the next two decades.

If Airbus can find a way to implement 3D printing in its design and production processes, it would represent a huge leap in the potential adoption of the technology by many other industries.

After all, if additive manufacturing could be useful for one of the most demanding manufacturing sectors, why can’t it be used for mass-production in dozens of other industries?

Don’t be surprised to hear some big news about the results of this project in the not-too-distant future.