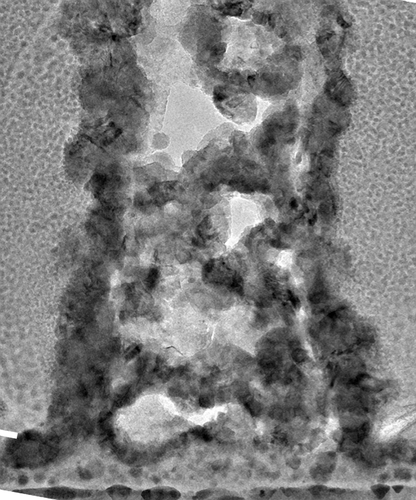

Caltech researchers have achieved a significant breakthrough in 3D printing metal objects at the nanoscale, with a size of 150 nanometers, comparable to that of the flu virus. The technique, led by Julia R. Greer and her team, involves the creation of tiny metal structures using a novel approach. Instead of perfection in atomic arrangements, they embraced disorder, resulting in nanosized metal parts that are unexpectedly three-to-five times stronger than their counterparts with more ordered atomic structures.

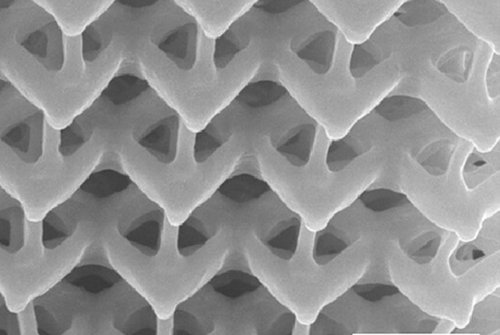

The process begins with a photosensitive hydrogel “cocktail” selectively hardened with a laser to create a 3D scaffold mimicking the desired metal object’s shape. These hydrogel structures are then infused with nickel ions, baked to remove the hydrogel, and chemically stripped of oxygen atoms to convert the metal oxide back into a metallic form.

This unconventional approach yields metal structures filled with defects, which would be detrimental on a larger scale but prove advantageous at the nanoscale. Defects prevent catastrophic failures by distributing deformation evenly throughout the material, increasing overall strength.

Greer’s team believes this method has opened the door to 3D printing metal structures at the nanoscale for various applications, including catalysts, storage electrodes, sensors, and microrobots. Their discovery challenges conventional wisdom and shows that sometimes, imperfections can be a feature rather than a flaw.

This research has been published in a paper titled ”Suppressed Size Effect in Nanopillars with Hierarchical Microstructures Enabled by Nanoscale Additive Manufacturing” in Nano Letters, and you can read it at this link.

Come and let us know your thoughts on our Facebook, Twitter, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.