Thanks to 3D printing, manufacturing has been graced with reduced costs, material waste, and faster design iteration, especially in the metal AM sector.

However, as demands skyrocket, the minor constraints of AM, including limitations in achieving certain tolerances and features in critical applications, are becoming more noticeable. High demand drives the quest for cost-effective solutions, albeit sometimes at the expense of quality, urging a look into post-processing methods for refining AM parts.

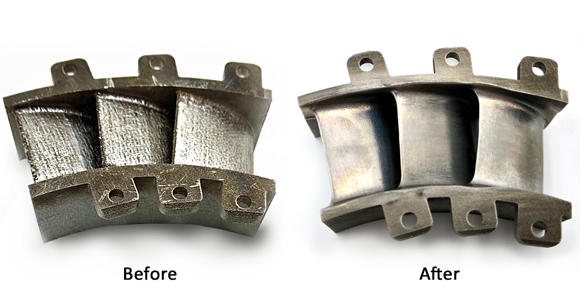

Enter Pulsed Electrochemical Machining (PECM), a novel material removal process spotlighted by Kirk Gino Abolafia from Voxel Innovations. Unlike conventional methods, PECM doesn’t rely on friction or heat. It employs electrochemistry to dissolve workpiece material, achieving superfinished surfaces, small features, and high repeatability. This is particularly useful on metal AM parts, making it a promising secondary machining and post-processing technique.

PECM shines in dealing with high-volume metal AM parts by significantly improving surface quality and resolution while reducing production costs. For instance, it can slim down the wall thickness of AM parts to less than 0.05 mm, a feat hard to achieve with AM alone. Moreover, its non-contact, non-thermal nature allows machining of sensitive areas without tool wear, making PECM a highly repeatable process.

Notably, PECM’s capabilities extend to critical aerospace and medical device components, showcasing its potential in enhancing performance, durability, and safety of AM products, especially in high-stress or temperature flux environments.

PECM stands out as a complementary solution to AM, addressing surface irregularities and feature size issues, ensuring metal AM parts meet the stringent requirements of critical applications while keeping manufacturing costs in check.

Source: metal-am.com

Come and let us know your thoughts on our Facebook, Twitter, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.