While brands like Adidas and Ecco have already set their sights on the 3D printed footwear market, there are still others finding exciting ways to improve this lucrative area of sporting goods. Rather than printing the whole shoe, Indian start-up ShapeCrunch opts for another route, relying on custom insoles to boost practical concerns such as comfort, value for money and, for the sportier consumers, durability and pain reduction.

ShapeCrunch has set out to prove that their insoles and a pair of affordable shoes are all you need. They are selling their orthotics primarily as a medical device. They go so far as to only sell their shoes through actual medical clinics and licensed physicians. ShapeCrunch’s insoles are thick with more pronounced supports and slopes that better conform to an individual’s shape.

According to the company, 3D printed insoles are not just cheaper, but also crucial in preventing running injuries. “This whole industry is not made by doctors, it is made by marketers,” says Nitin Gandhi, co-founder of Shapecrunch. “When high heels were made the doctors should have come forward and said that this is not something that is going right. It’s marketing, right, you can do anything and sell anything. That is something which we are not into.”

Modernising Running Shoes & Pain Reduction

ShapeCrunch are dead serious about the medical aspect, getting doctors to weigh in on their designs. Their website actually has a whole section on various foot problems one can face and even locations of clinics. To obtain one of their insoles, you can place an order on their website or through a physician. Physicians can also become partners for the company’s program.

So far, 100’s of doctors have signed up to be part of ShapeCrunch’s programs, spanning the US, India and Singapore. This system ensures that the consumer is getting a precise version that suits their own feet, taking advantage of 3D printing’s customisability.

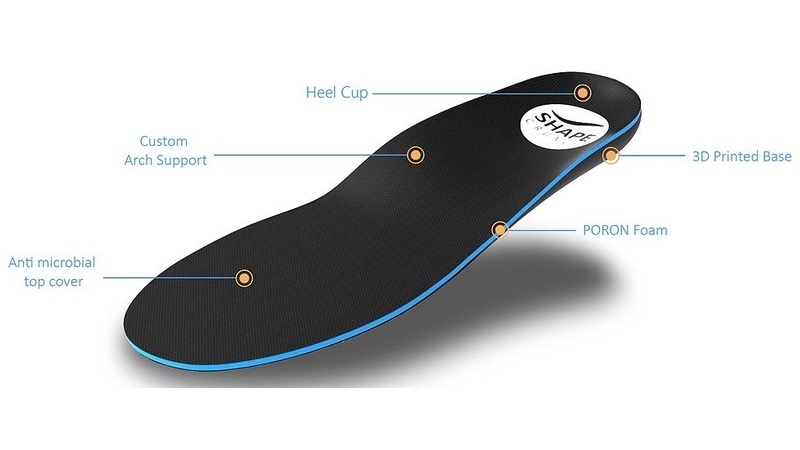

It’s a very data-driven method, using precise zones to cater to the patient’s specs. The company also provides orthotics in two broad categories: formal shoes and running shoes. They advise users to switch orthotics when they switch shoes.

Developing Custom Insoles

Since traditional shoes require vacuum pads or POP casting to obtain an impression of the feet, they are quite manual. ShapeCrunch, on the other hand, develops the insoles from 3 images and then automates the process. The company provides measuring device to the physiotherapists so they can measure shoe size and foot width.

“One is the plantar image. It is mapped with the sides of the shoe,” Gandhi says. “The second image is of the side. We check how much arch is required. Also the starting point, ending point, everything. Then we have the back image from where we see how much deviation is there (in the heel). We have decided on some limits for arch, etc.”

The doctors will then ask a few medical questions and inquire about the consumer’s medical history. They take pain areas for both of the feet into account and upload it to the company’s app. ShapeCrunch uses all this data to derive a perfect orthotic for the patient. This system is crucial in developing better foot care and specialising products to suit the individual’s medical needs. Hopefully, such programs can one day cater to the infirm or the elderly all over the world.

Featured image retrieved via gadgets360 website.