The mechanical properties of 3D printed thermoplastic materials have been fairly well explored at this point. Sure there is always room for improvement… gradually, over time, researchers will create new polymer blends, or new filled plastics, and there will be incremental gains in strength.

Eventually, the engineering polymer materials will be comparable to certain metals in terms of weight and strength. All good.

But there is more to 3D printed polymers than mere specific strength.

Several companies have been playing around with the electrical properties of the feedstocks, for a while, with the intention of making them conductive and static-dissipative.

In this post, we will take a look at static-dissipative, or so-called ESD safe materials.

ESD, or electrostatic discharge, is the discharge of electricity between a statically charged object (such as your hand), and another object of a different potential, such as a metal doorknob.

You know what happens next: you touch the doorknob, you get a shock.

If that happens every single day for a year in a classroom, then it can leave a Pavlovian fear of metal doorknobs (speaking from experience).

Human beings can begin to feel ESD on the skin at around 2000-3000 volts. Obviously the current is negligible, otherwise it would kill you.

Small electronics components such as the transistors on an IC, however, can be utterly destroyed by ESD with voltages lower than just 10 volts of static electricity.

That’s not to mention the arcs caused as a statically charged object tries to ground itself across an air gap. You don’t really want these sparks flying around as you fill your fuel tank with petrol.

Both of these reasons and more are why product designers and engineers need ESD safe plastics. The protect ESD sensitive electronic components during manufacture and stop gas stations from exploding.

In terms of ESD safe materials, they can be divided into two main groups.

These are conductive, and static-dissipative materials.

Conductors have low electrical resistance and can transfer electric charge via the bulk material or over the surface. In ESD application, they are used in those ESD bracelets that you wear on your wrist and connect to ground. They are also used on those plates that you stand on when entering an ESD controlled area, such as in an electronics factory.

Conductive vs. Static-Dissipative Materials

Conductive materials have a very low electrical resistance, allowing electrons to flow easily across their surface or through the bulk of the material. Charge flows quickly from one conductor to the next.

With static-dissipative materials, the charge flows more slowly. When an arc occurs, it does so at a slower velocity, and with lower energy as it tries to reach ground.

Plastics are insulators. They hold charge, and have a high electrical resistance. To have a path to ground, conductive fillers must be added to the material in order to be dissipative.

In order to be classed as an ESD safe material, the surface resistance of that material must fall within the range of 105 Ω and 1011 Ω. If it is less than that range, it is conductive. If it is more, then it is an insulator.

Here are a few different materials which are designed for ESD applications covering the main plastic printing methods.

Extruded Materials

If filament deposition is your thing, then you have a lot of options for ESD safe filaments.

Most of them modify the surface resistance by addition of some form of carbon.

ESD safe materials are available in a wide variety of different polymer flavors including high-temperature nylon, TPU and polycarbonate. Ultimaker has a great overview of ESD safe materials which are also tested on their machines, right here.

Sintered Materials

The ESD friendly sintered plastic feedstocks are less numerous than their extruded filament counterparts. But they are still commercially available for anyone who owns an SLS machine capable of printing plastics.

Plastic company Igus has a sintered material named iglidur I8-ESD, for example. It has a high abrasion resistance and is electrostatically dissipative. According to the website, it is compatible with most SLS Machines.

Photopolymer Resins

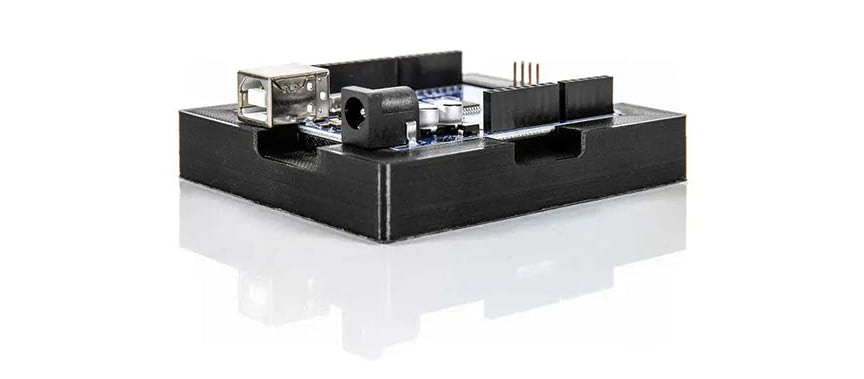

Until recently, options were limited if you needed an ESD-safe photopolymer resin for printing. In 2023, Dutch company Liqcreate, known for manufacturing some of the strongest SLA resins on the planet, released an affordable and rugged ESD-safe resin material suitable for use with most consumer-grade resin printers.

The Liqcreate ESD resin falls within the range of static dissipative materials, making it ideal for producing ESD-safe parts. It has an opaque black appearance and is compatible with various consumer and professional grade 3D printers in the range of 385-405nm, allowing the production of printed objects with isotropic electrostatic dissipative characteristics.

Next article, we will take a look at the conductive feedstock options. That is the materials with surface resistance of less than 105 Ω.