Last week we took a look at ESD safe materials for 3D printing. These are materials that are safe against electrostatic discharge, and have uses largely in electronics manufacturing.

This article, we will look at polymer composites with lower surface resistivity, in other words, electrically conductive 3D printing feedstocks.

Conductive materials have a surface resistivity of less than 1 x 10 5 Ω/ sq. This is compared to dissivative (ESD) materials which lie in the range of 1 x 10 5 Ω/ sq to 1 x10 11 Ω/ sq.

Conductors allow electricity to flow, and so have a bunch of potential uses, ranging from 3D printed circuits, wearable tech and maybe even one day, conductive substrates for electroplating.

Here are a few options for you, depending on what type of additive manufacturing process you are using.

Extruded Materials

For a while, filaments have been available in conductive form. Similar to ESD materials, conductivity generally tends to be manipulated by addition of some form of carbon to the feedstock during filament manufacture.

There are a lot of smaller companies offering these conductive filaments, yet strangely we don’t see much from the larger companies.

Fans of tougher thermoplastics such as ABS, TPU and PC will be pleased to know there are plenty of options for conductive variants of this polymer. A google search of the term “conductive X filament” (with “X” being your thermoplastic of choice) will yield a fairly huge selection to choose from.

Sintered Materials

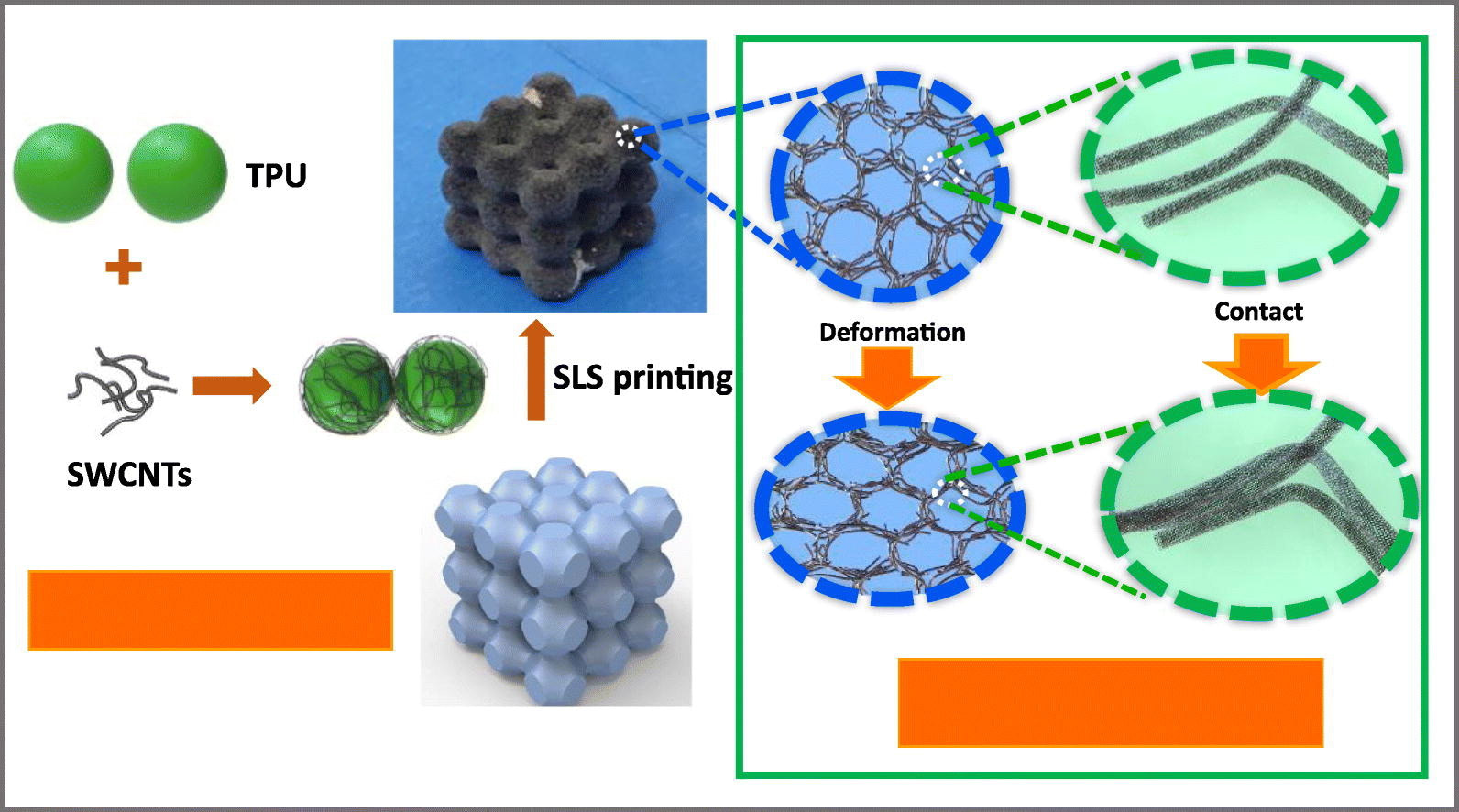

Anyone with access to a SLS machine will be pleased to hear that there are options available (and in development) to those who enjoy sintering things.

There is currently research underway into addition of metallic fillers such as copper and aluminium also.

There are a variety of methods involved in manufacturing electrically conductive SLS materials. Many involve the mixing of carbon into the feedstock, while others focus on actually coating the actual particles with a conductive filler, as you can see in the image below.

A lot of research is focused on the shape and size of the additive particles (for example spherical vs. flakes), to determine the optimum parameters for successful bonding and increased electrical conductivity.

Photopolymers

Similar to the ESD materials of last week, the selection of conductive resins is smaller than the extrusion & sintering feedstocks. Last week we pointed out that mixing carbon particles into a resin can result in the contents settling, which can require constant mixing immediately before printing.

This is one possible explanation for the small selection of these resins available.

While there aren’t many options for SLA/DLP printing conductive materials available commercially, conductive resins are being researched by various universities around the world, so there is potential for the market to grow, once manufacturers iron out the creases, whatever they may be.

This team from Yeungnam University, South Korea, for example, has manufactured a Polyacrylate Resin Solution with Polyaniline Nanofiber and Graphene additives, for improved conductivity.

Another team, from Georgia Institute of Technology and Xi’an Jiotong University, has mixed multi-walled carbon nanotubes (MWCT) with resins and demonstrated that they show conductivity. In fact, these research resins have been shown to be very useful indeed, having been shown to be useful for electrically activated shape memory composites.

Final Thoughts

So, those are basically your options where it comes to conductive polymer materials. Most products involve the addition of some form of carbon (typically graphene) to change the surface resistivity, but we are seeing researchers adding metals into SLS feedstocks to enhance conductivity.

Of course, if you want something truly conductive, you will be better off sticking with metal materials. Plastics are great at insulating, and not so bad at ESD protection, but for conductivity, they aren’t so great.

It’s worth remembering that while a conductive polymer may be 10^10 times more conductive than a non-conducting filament, it is still 10^10 times LESS conductive than copper.

So bear that in mind when buying a conductive polymer material, and if in doubt…always read the datasheet.