Use Case

Optimize Fluid Dynamics

A new eBook from 3D Systems is available for download, highlighting many of the cutting edge industries making the most of additive manufacturing in the vast and varied world of fluid dynamics.

More Complexity

It’s difficult to say what the single largest benefit of AM is to fluid systems. There are so many benefits, all intertwined. Greater design freedom allows more complex structures and fluid channels to be integrated into a structure. This can result in reduced need for fasteners, seals, and an increase in part strength where these potential failure points have been removed.

You can’t have a gasket blow if you don’t need a gasket.

And of course, reduced part count can lead to significant weight reductions too, which is ideal for aerospace applications. With that in mind, let’s look at our first example from the eBook about how fluid dynamic systems have benefited from additive manufacturing.

Aerospace

Fuel injectors for rocket engines are typically complicated to make, and can require up to 200 components for an assembly in some cases. Keeping high pressure, high/cryogenically low temperature fluids in check requires a lot of seals and fasteners, and quality control.

The German space agency, DLR, has been working on reducing part complexity and mass for their own fuel injectors, and they have benefited from increased geometric complexity afforded by additive manufacturing.

The DLR goal on this project was to increase performance and reduce weight on a coaxial injector head for their rocket engine. By choosing a metal additive manufacturing approach, they were able to achieve both of those goals.

In this instance of injector design, DLR were able to achieve a part number reduction from 30 parts down to just one part, resulting in a 10% mass reduction and the removal of potential failure points from where the components normally would have been mated together in an non-AM design.

For this task, the researchers utilized the 3D Systems DMP Flex 350 / DMP Factory 350 systems for printing, and the components were printed with the Laserform-ni718 super nickel alloy.

Microfluidics

Microfluidic systems are used in research (and especially in medicine) for manipulating delicate fluids around micron-scale channel diameters.

Typically this has been very expensive to achieve with traditional processes, but thanks to additive manufacturing, precise geometries can be manufactured for small scale fluid management.

This has become valuable during the pandemic, as demonstrated by researchers at Imperial College, London.

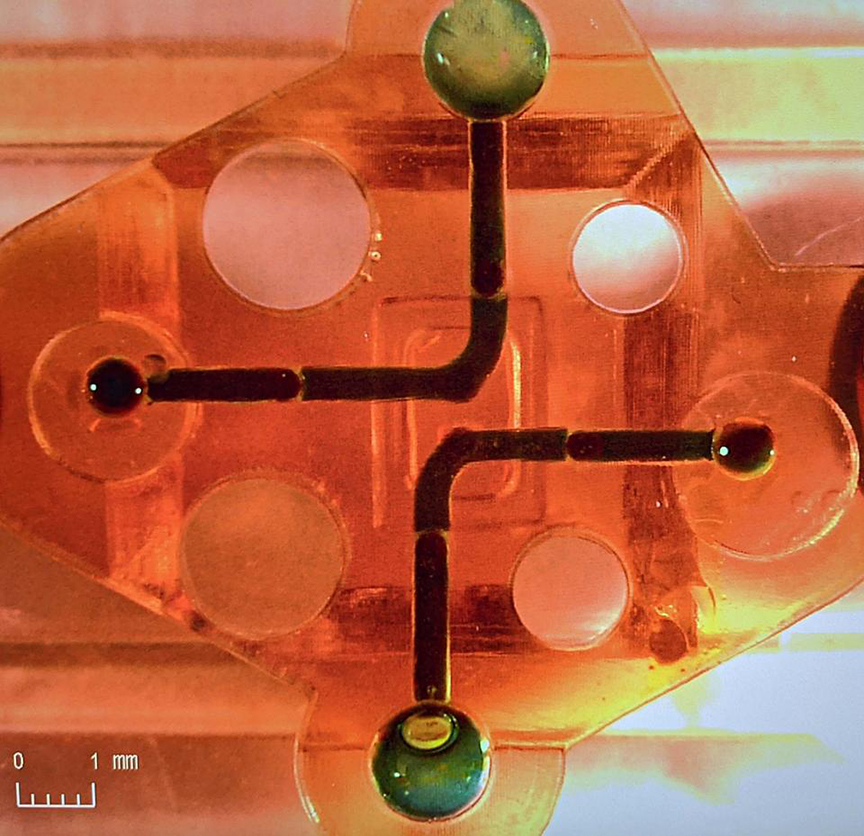

Researchers there have been working on a project named Lacewing, who have been using bio-compatible resin materials in the fabrication of microfluidic devices and other components for their lab-on-a-chip pathogen detection systems. Each Lacewing microfluidic cartridge is roughly 30 mm x 6 mm x 5 mm. You can see a closeup of the cartridge below.

The Lacewing platform is a molecular diagnostic test that works by identifying the DNA or RNA of a pathogen within a patient sample. Due to being in contact with DNA, the system needed to be constructed with bio-compatible materials, so as not to interfere with the reactions being carried out. The researchers have reported that the 3D Systems resin used yielded great results for bio-compatibility.

“With the Figure 4, we’re now able to rapidly print parts with complex internal 3D fluidic channels for transporting sample fluid to different sensing areas on the chip, greatly improving our microfluidic production capabilities,” Matthew Cavuto, PhD student and research assistant at Imperial.

“Figure 4 has changed what I can print, or what I think I have the capability of creating. In terms of resolution, speed, surface quality, range of materials, and biocompatibility, there’s nothing that compares to Figure 4, and I’ve probably used every type of 3D printer you can imagine.”

As you can see, AM is offering its boundless design freedom to a variety of critical industries, across a wide range of materials and over many different AM processes.

Be it metal or polymer, powder or resin, large or small scale, AM offers a wide array of solutions to engineers working in the thermofluid domain.

You can download the eBook yourself and read more about how AM can help your fluid systems projects over at 3D Systems website.