It has been a while since we have covered anything in the domain of bioprinting.

It’s not that we don’t like writing about bioprinting around here, but given the current state of technological readiness there is a very fine line between a 3D printed heart, and a 3D printed steak, functionally speaking.

But bioprinting goes beyond simply just (eventually) printing large transplantable organs. The precision of the CNC guided bioprinting toolhead can deliver materials of various properties to make other biological systems too.

And that is exactly what Prellis Biologics have been doing with their 3D printed lymph nodes, as revealed in a recent press release.

Prellis Biologics had previously dabbled in the realm of 3D printed organoids (such as kidneys) but have since shifted their expertise to smaller organoids such as lymph nodes, which are a major component of the human immune system.

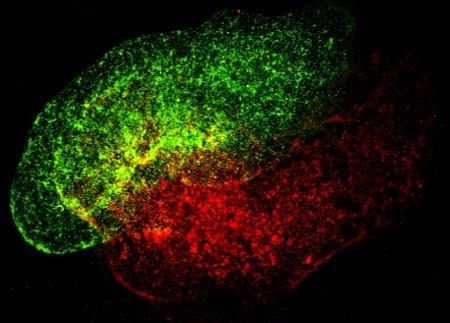

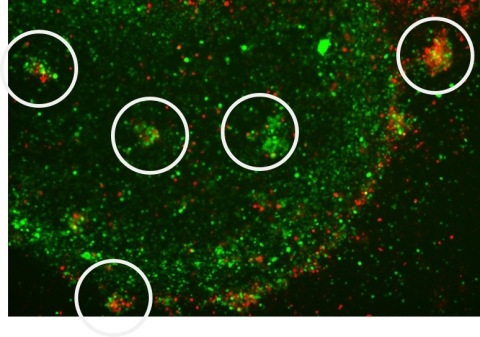

The Prellis Biologics platform, dubbed “EXIS” (Externalized Immune System) utilises the company’s proprietary bioprinting technology to manufacture synthetic lymph nodes, which are then populated with human immune cells. The synthetic organoid can then be tested with vaccines to see how the immune cells produce antibodies.

“EXIS is an ultra-fast, animal-free platform for raising human antibodies to human proteins,” said Kevin Chapman, CSO. “In a matter of a few months, the team has been able to generate state of the art human antibody libraries against a whole host of immune-oncology targets. We are extremely excited to extend the system to human immunogenicity testing, and patient antibody mining.”

Prellis uses a holographic printing system which uses a laser to cure objects in a vat (similar to common photopolymer printing methods), which are able to match and accurately replicate human organ and tissue structures for R&D, and ultimately, organ transplantation.

The EXIS platform has already been utilized in research against the coronavirus, when Prellis Biologics produced 960 synthetic human lymph nodes for testing covid-like vaccines. The work was a success with the company announcing that their method had produced over 300 virus-specific antibodies thanks to the printed lymph nodes. That\s quite a lot apparently.

“Three hundred virus-specific IgG antibodies is a tremendous number to have at this stage,’ said Erin Stephens, PhD and Director of Tissue Engineering at Prellis.

”Our pipeline for class-switched antibodies has produced an order of magnitude larger pool than the typical antibody development program.”

So, to answer the question posed by the headline, we refer you to Betteridge’s Law of Headlines. That is to say, any headline that ends with a question mark, can normally be answered in the negative.

We likely won’t be seeing printed consumer grade lymph nodes available to the public any time soon, but in the meantime, the little organoids are definitely earning their keep in the domains of virus research. And the $14.5 Million Series B Investment announced by the company in December will certainly keep things active in that area for a while.