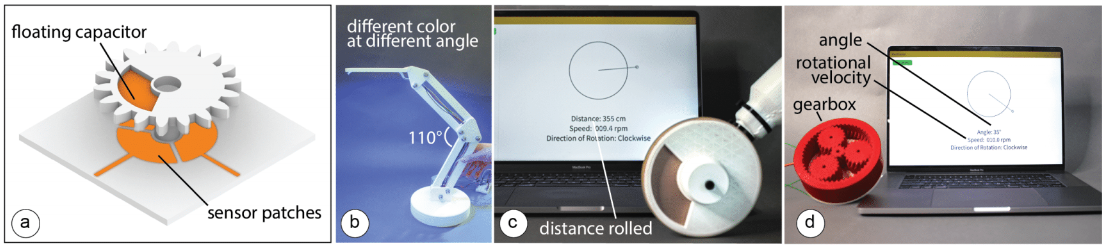

MIT researchers have developed a new system called MechSense that enables makers to 3D print sensors directly into rotational mechanisms using conductive 3D printing filament. This innovation allows devices to sense their angular position, rotation speed, and direction of rotation.

CAD Plugin

The researchers created a plugin for the computer-aided design software SolidWorks to streamline the fabrication process, automatically integrating sensors into a model, which is then sent directly to the 3D printer.

MechSense could revolutionize the way engineers prototype devices with rotating parts, such as turbines or motors, by incorporating sensing directly into their designs. This technology could be particularly useful in creating tangible user interfaces for augmented reality environments, where sensing is crucial for tracking user movements and interactions.

Floating Capacitor

Capacitive sensing was utilized to incorporate sensors into rotational mechanisms without disrupting the device’s movement. As the device spins, the floating capacitor on the rotating plate overlaps each stationary patch, and the patches individually detect the resulting change in capacitance. This information is then converted into estimations of angular position, direction of rotation, and rotation speed.

“A lot of the research that we do in our lab involves taking fabrication methods that factories or specialized institutions create and then making them accessible for people,” said researcher Marwa Al Alawi.

“3D printing is a tool that a lot of people can afford to have in their homes. So how can we provide the average maker with the tools necessary to develop these types of interactive mechanisms? At the end of the day, this research all revolves around that goal.”

The researchers used MechSense to prototype various devices, including a smart desk lamp, a planetary gearbox, and a distance-measuring wheel. Future plans for the technology include testing different materials, increasing robustness against external noise, and developing printable sensors for other types of moving mechanisms.

Come and let us know your thoughts on our Facebook, Twitter, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.