It wasn’t so long ago that if you wanted to 3D print ESD-safe components, your options would have been limited to using SLS or FDM materials for the task.

Sure, there were some esoteric ESD resins available, but they required special hardware to mix the conductive carbon particles before being printed.

Well, those days are long behind us now, because Liqcreate (manufacture of premium photopolymers for SLA, DLP & MSLA 3D printing) has released a low-cost ESD resin material that can be used on pretty much any consumer grade resin printer.

ESD-safe 101

ESD, or electrostatic discharge, is the discharge of electricity between a statically charged object (such as a human being) and another object of a different potential, such as an integrated circuit packaging.

Small electronics components such as the transistors within an IC can be damaged by ESD with voltages lower than just 10 volts of static electricity. The resulting arcs caused by statically charged objects across an air gap can also cause explosions, especially in enclosed spaces rich with flammable fluids.

Therefore, to prevent risk of component damage (or explosion), it is recommended to use ESD protection in the workplace. This can range from floor treatments that prevent the buildup of static charge, to components used for handling delicate parts.

Conductors and Insulators

Resistivity is the electrical resistance of a conductor of unit cross-sectional area and unit length. A characteristic property of each material, resistivity is useful in comparing various materials on the basis of their ability to conduct electric currents. High resistivity designates insulators (such as plastics), and conductors (such as metals) have low resistivity .

Conductive materials have a low resistivity, allowing electrons to flow easily across their surface or through the bulk of the material. Charge flows quickly from one conductor to the next.

With static-dissipative materials, the charge flows more slowly. When an arc occurs, it does so at a slower velocity, and with lower energy as it tries to reach ground.

Plastics are insulators, and they hold electrical charge. To have a path to ground, conductive fillers must be added to the material in order to be dissipative, and therefore ESD-safe.

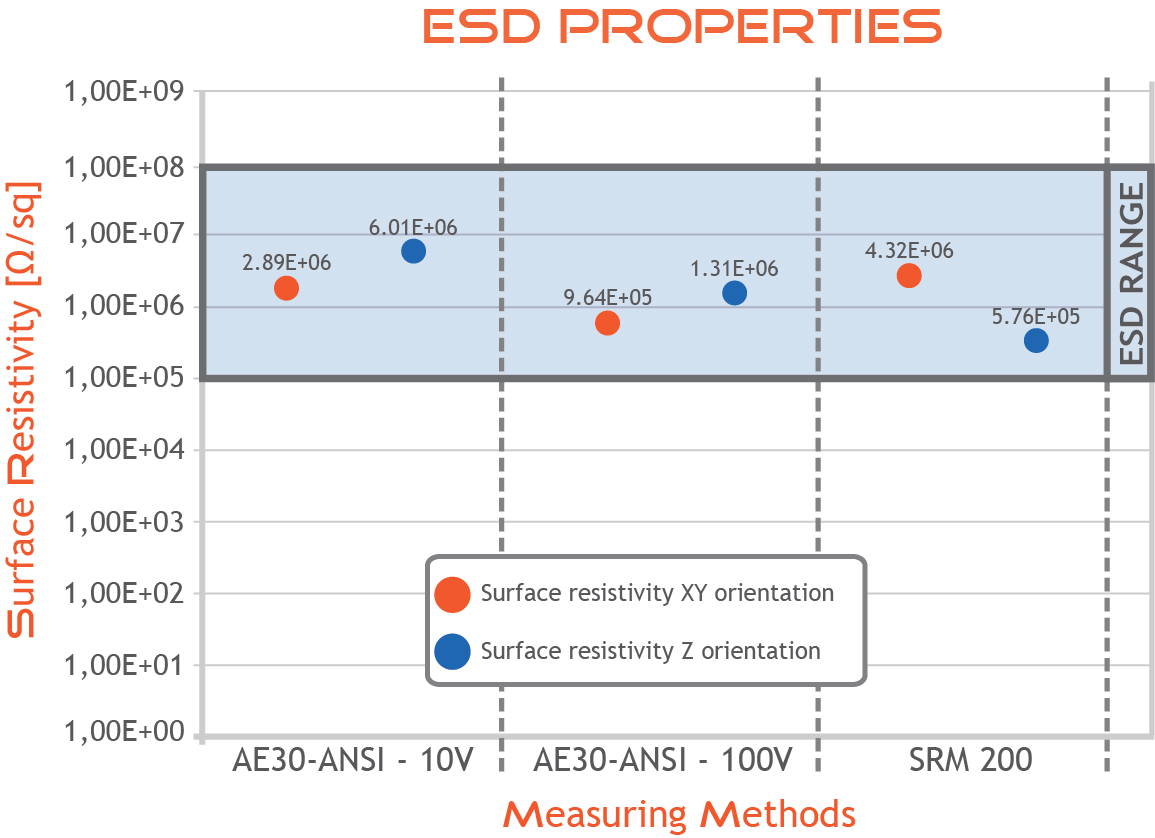

In order to be classed as an ESD safe material, the surface resistivity of that material must fall within the range of 105 Ω and 1011 Ω. If it is less than that range, it is conductive. If it is more, then it is an insulator.

As you can see in the graph above, the Liqcreate ESD resin sits comfortably in the static dissipative region, meaning it is well suited for producing ESD-safe parts.

Liqcreate ESD Resin

Now that we have taken a look at the ESD properties of the new Liqcreate ESD resin, let’s take a look at some more details.

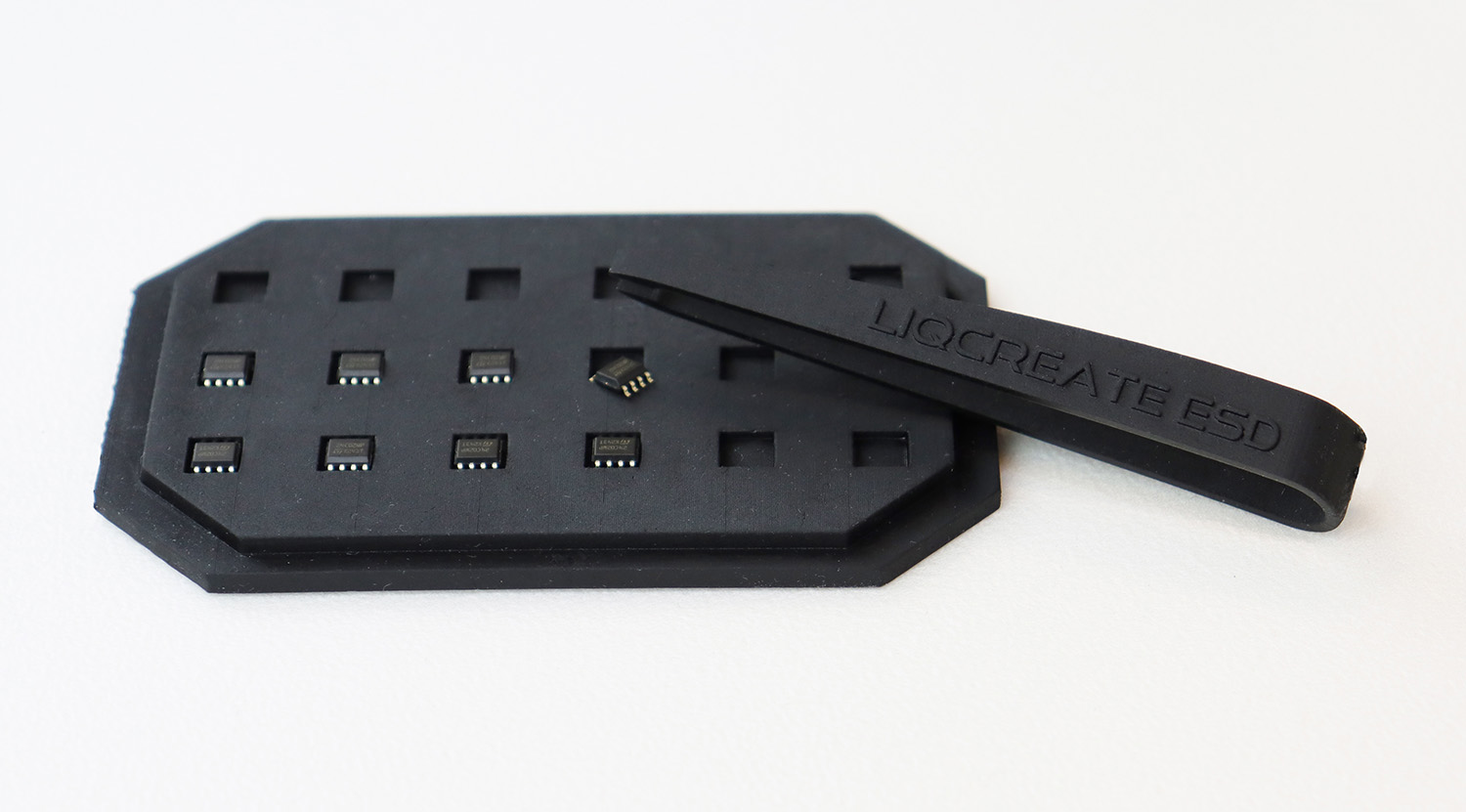

Liqcreate ESD has an opaque black appearance, and is compatible with open DLP, LCD, and SLA 3D printers operating within the 385-420 nm range, allowing for the production of printed objects with isotropic electrostatic dissipative characteristics. You can see a list of compatible printers at this link.

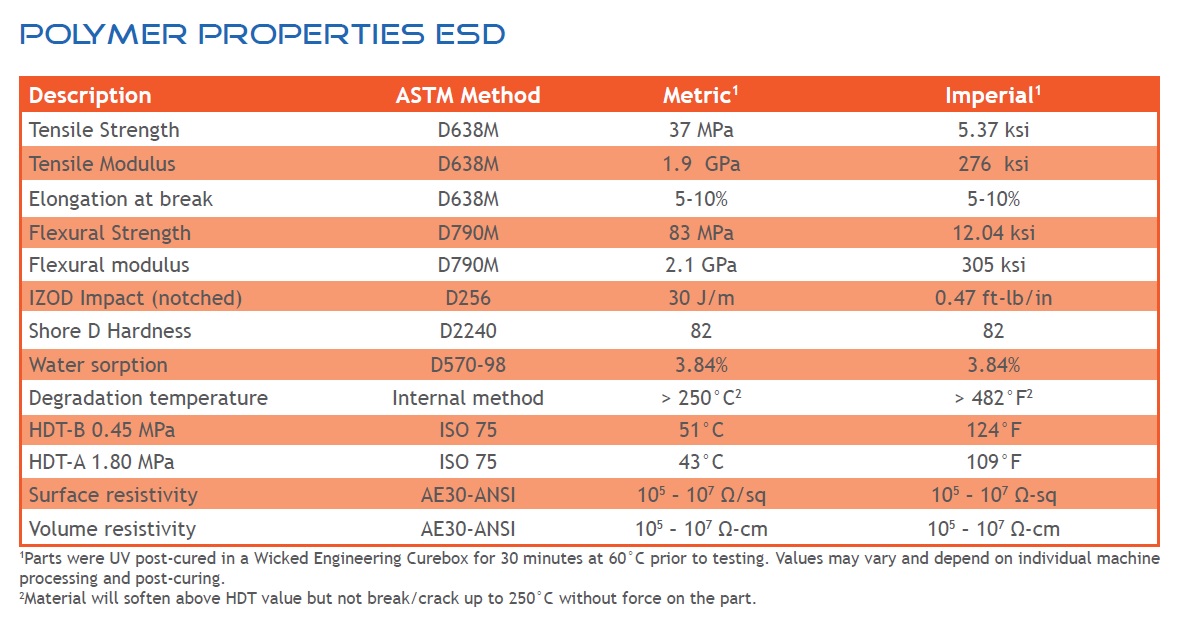

When cured, Liqcreate ESD has a tensile strength of 37 MPa and a tensile modulus of 1.9 GPa, making it suitable for functional applications. For more information on how to print with their ESD resin, you can read the printing guidelines over at this webpage.

You can see the list of other material properties of the Liqcreate ESD resin in the table below.

Of course, being responsible for the development of their own resin materials and having a well equipped R&D department at their headquarters in the Netherlands, Liqcreate can also develop custom ESD materials and masterbatches according to clients’ needs.

For example, if a client requires an elastomeric or flexible ESD material with a Shore A ranging from 45 to 95, or high temperature ESD material (for chip manufacturing cycles at elevated temperatures), then they can get in touch with Liqcreate and the company can work with the client to develop the custom resin. Customers needing bespoke resins can reach out to the company via their website.

Availability

Liqcreate ESD is available now.

“Due to its tough properties and unique price point our new ESD resin is perfect for small batch manufacturing” said Ruben Bosch Sales & Marketing Executive.

That price is €139.95 for a kilogram, and the resin can be obtained from the company website. So if you are in need of a rugged resin for the manufacture of custom jigs, fixtures and tools to protect critical electronics components from static discharge, then you can head on over to the Liqcreate ESD product page at this link, for more information, or to place an order.

Come and let us know your thoughts on our Facebook, Twitter, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.