New York-based company Senvol has demonstrated a machine learning approach to developing material allowables for additive manufacturing (AM). This approach was shown to be more flexible, cost-effective, and time-efficient than the conventional approach.

The work was undertaken as part of a US government contract that Senvol was awarded to apply its machine learning software, Senvol ML, to enable a path to rapid development of material property allowables for AM. An “allowable” is a material parameter determined through testing, and is typically applied in safety critical systems. For example, a material can have an “allowable stress”.

The machine learning approach uses statistical analysis to identify patterns in data from AM experiments. This data can then be used to predict the properties of AM parts, without the need for extensive testing.

“I was very pleased to join Senvol’s team for this program,” said Dr William E Frazier, retired Chief Scientist for Air Vehicle Engineer at NAVAIR and current President of Pilgrim Consulting LLC.

“Senvol’s machine learning-enabled approach directly addresses a major industry challenge: the rapid and cost-effective development of Additive Manufacturing material property allowables.”

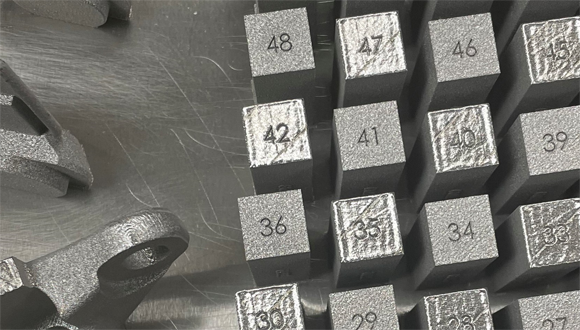

This approach was demonstrated using a 17-4 PH Stainless Steel material processed via a Powder Bed Fusion AM machine. The results showed that the machine learning approach was able to predict the properties of the AM parts with a high degree of accuracy.

Accelerated Development

The machine learning approach has several advantages over the conventional approach. It is more flexible, as it can be used with any AM process or material. It is also more cost-effective, as it requires less testing, and it is more time-efficient, as it can be used to develop allowables more quickly.

“Material allowables development is a very expensive and time-consuming endeavor,” said Annie Wang, President at Senvol.

“Senvol’s program was very successful in demonstrating a new approach to additive manufacturing allowables development that leverages machine learning. We were very pleased with the results and look forward to continued work in this cutting edge area.”

The machine learning approach is still under development, but it has the potential to revolutionize the way that material allowables are developed for AM, leading to faster and more cost-effective development of AM parts.

Come and let us know your thoughts on our Facebook, Twitter, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.