The 3D printing landscape is undergoing a transformation, and the unlikely heroes in this revolution are insects. With growing concerns about plastic waste generated by traditional 3D printers, researchers are exploring new solutions to create sustainable and biodegradable printing materials. Enter chitosan, a polymer derived from chitin extracted from dead black soldier flies.

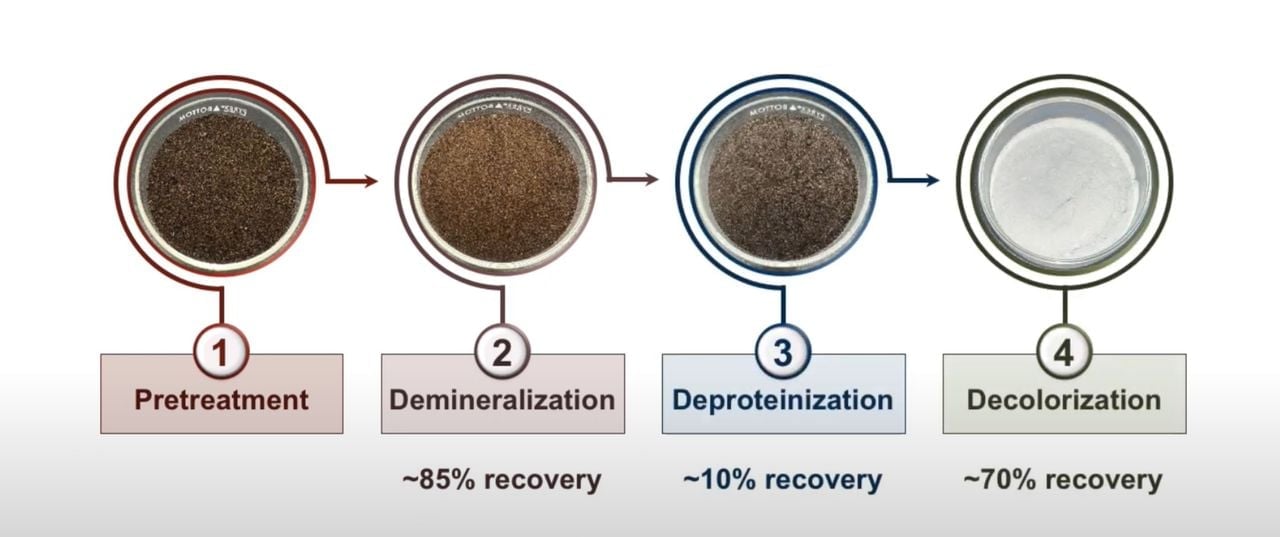

In a recent research paper presented at the American Chemical Society’s fall meeting, a team of academics unveiled the creation of functional bioplastics using chitin from fly carcasses. These flies are typically used in the farming of larvae for animal feed and waste management, leading to a surplus of deceased flies (gross!). By efficiently extracting and purifying chitin, researchers have produced a polymer called chitosan, which holds promising potential for 3D printing applications.

While the initial focus was on developing a highly absorbent hydrogel, the research team aims to expand chitosan’s capabilities. The vision includes producing bioplastics akin to widely-used 3D printing materials such as polycarbonate and polyurethane.

As this research progresses, there is hope that sustainable and eco-friendly printing materials will replace the current plastic-heavy options, alleviating worries about plastic pollution and its adverse effects on ecosystems.

While we may be at the early stages of this insect-carcass powered revolution, the potential for insects to reshape the future of 3D printing is promising. As researchers continue to refine the process and expand the range of chitosan-based materials, we may soon witness a transformative shift in the 3D printing industry towards a more sustainable and environmentally-conscious future with bio-based plastics from not only plants, but now also from insects.

And why not? Chitin is one of the most common biopolymers on Earth, being second only to cellulose. May as well use it.

Come and let us know your thoughts on our Facebook, Twitter, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.