A recent paper from Graz University of Technology has unveiled a means of 3D printing with supercooled liquids, which could greatly increase the speed of additive manufacturing. The research focuses on one material in particular, sodium acetate trihydrate, which is a salt hydrate.

Salt hydrates exhibit unique properties when subjected to supercooling, which is the process of lowering the temperature of a liquid below its freezing point, without it becoming a solid. Sodium acetate trihydrate was preferred over other salt hydrates as it is easily available, and exhibits low toxic behavior compared to other salt hydrates.

Supercooled liquid salt hydrates can rapidly crystallize, potentially allowing for significantly faster printing speeds, presenting an exciting opportunity to enhance the efficiency of 3D printing processes.

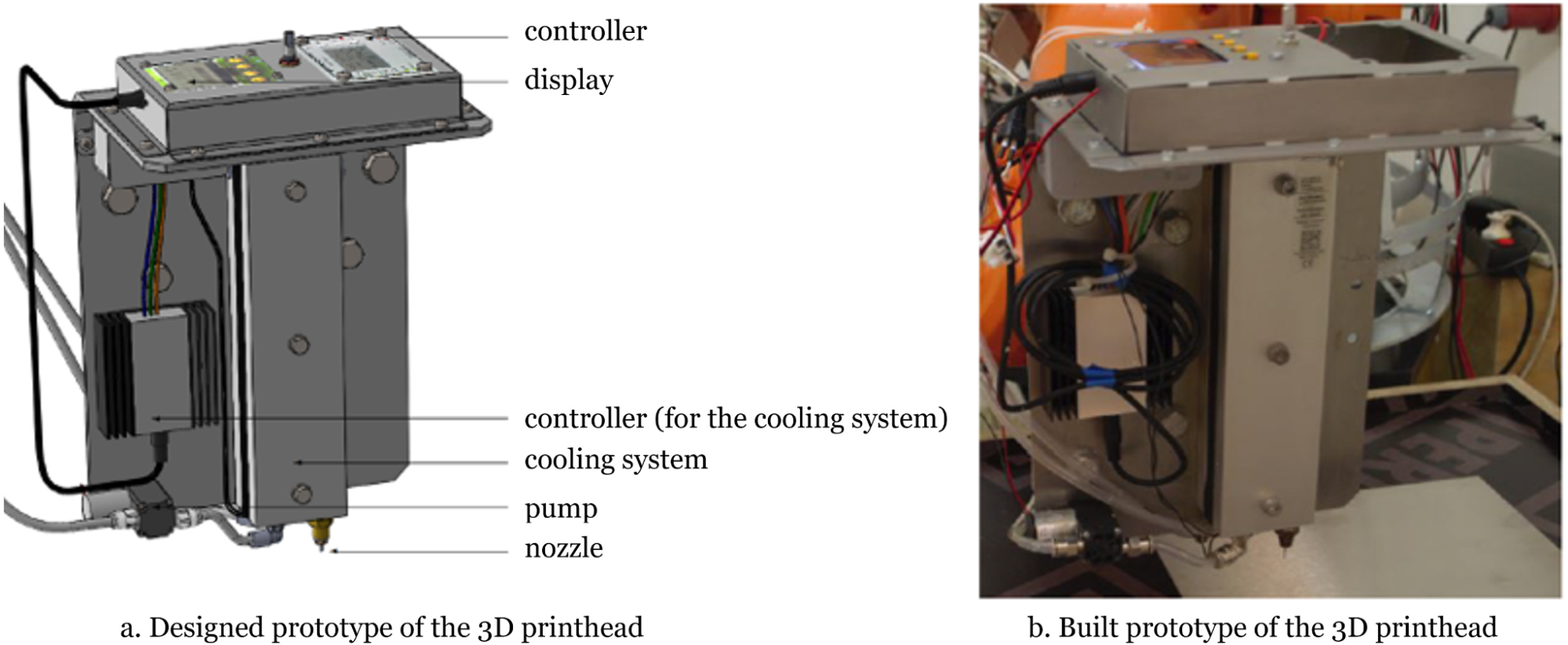

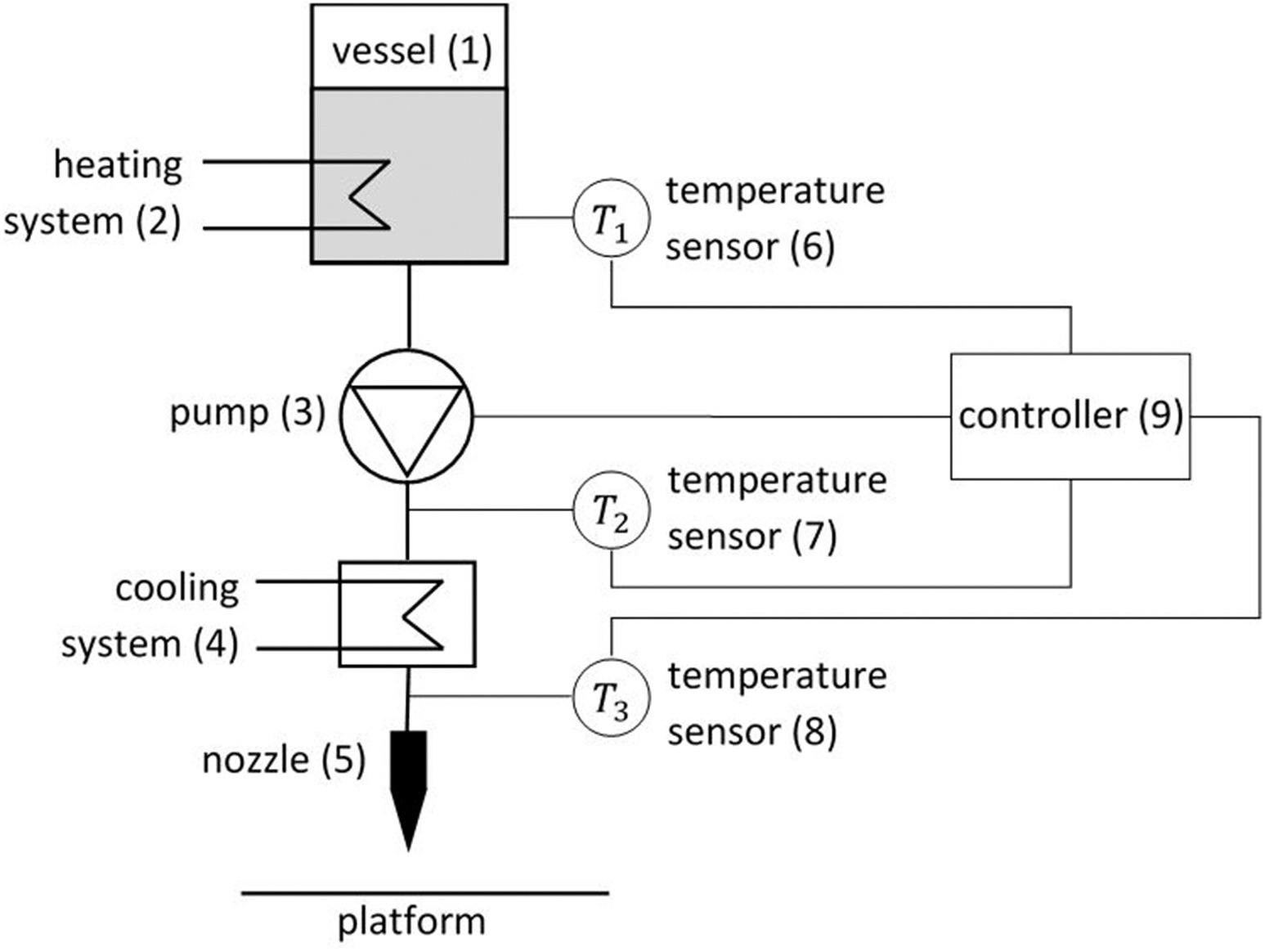

To validate the theoretical framework, experiments were conducted using a robot-mounted printhead designed for printing sodium acetate trihydrate. Material properties, such as density, surface tension, and viscosity, were carefully considered in the experiments. The results indicated a strong correlation between theoretical predictions and practical outcomes. The experiments showcased the ability to control the geometry of the deposited layers.

As mentioned previously, one of the most exciting aspects of 3D printing with supercooled liquids is its potential for increased printing speed. The research paper highlighted that this method could achieve nozzle exit velocities of up to 6.4 m/s, translating to printing speeds of a hefty 53 kg/h. This advantage positions supercooled liquid deposition as a compelling alternative to traditional 3D printing processes, particularly for applications requiring rapid production.

The ability to control geometry shapes during the printing process and the advantages of water-soluble salt hydrates make this technique promising for multiple applications, including art, restoration, and mold production.

The researcher (Markus Brillinger) has concluded the paper by acknowledging ongoing research efforts to further refine and industrialize the process, addressing challenges related to process control and preventing back-crystallization. In addition, Brillinger is also investigating other salt hydrates, including aluminum potassium sulfate dodecahydrate, and magnesium chloride hexahydrate.

You can access the pre-proof paper, titled “3D printing of supercooled liquids: Modeling and verification on sodium acetate trihydrate” in the Additive Manufacturing journal, at this link.

Come and let us know your thoughts on our Facebook, Twitter, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.