Carbon, a company unknown until now, just released a groundbreaking 3D printing technology which is 25 to 100 times faster than currently available commercial PolyJet or SLA machines. It is a true quantum leap forward for 3D printing speed!

Here is a TED talk by Joseph DeSimone showing this revolutionary process live on stage and explaining the technology:

The company uses new 3D printing process they named “Continuous Liquid Interface Production” or CLIP. This new process has some similarities with DLP SLA but uses additional lens like oxygen permeable layer in the resin vat that enables changing pulses of UV light and oxygen to build the object in fast continuous flow.

Joseph DeSimone, company CEO, Professor Edward Samulski and Dr. Alex Ermoshkin developed CLIP as they saw oxygen preventing polymerization in their university classes.

The process is described on sciencemag.org by its creators as:

Additive manufacturing processes such as 3D printing use time-consuming, stepwise layer-by-layer approaches to object fabrication. We demonstrate the continuous generation of monolithic polymeric parts up to tens of centimeters in size with feature resolution below 100 micrometers. Continuous liquid interface production is achieved with an oxygen-permeable window below the ultraviolet image projection plane, which creates a “dead zone” (persistent liquid interface) where photopolymerization is inhibited between the window and the polymerizing part. We delineate critical control parameters and show that complex solid parts can be drawn out of the resin at rates of hundreds of millimeters per hour. These print speeds allow parts to be produced in minutes instead of hours.

Here is an animation that can help you visualize it:

The company claims it has independent test that back the indicated speed increase. Here is the comparison chart showing that it takes only 6,5 minutes to 3D print object that takes 3 hours to print on PolyJet machine:

One additional feature of CLIP is that there are almost no layers so there is a sharp increase in print quality, final object precision and smoothness.

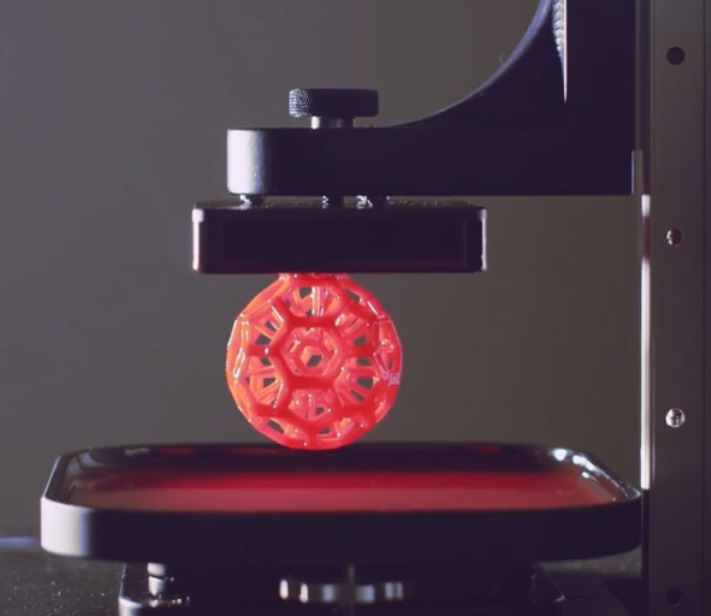

Here is video where you can see CLIP 3D printer by Carbon3D in action:

Even taking in consideration that is played at 7 times the speed still makes it incredibly fast for todays standards.

Here is a video of CLIP 3D printing an Eiffel tower model in less than 7 minutes:

Carbon 3D has demonstrated that CLIP can be used with variety of elastomers both flexible and rigid:

They have the technology and the funding needed to develop it further since they received 41 million USD in funding from Sequoia Capital and Silver Lake Kraftwerk until now. Looks like future is bright for this technology and company.

How will competition respond? Will someone buy Carbon3D or merge with them? This new player will certainly shake up the scene!

This is truly revolutionary technology which will hopefully reach average consumers in near future!