In a pretty cool story from Australia, ABC news described how a Tasmanian teacher found a way to benefit both the environment and the additive manufacturing industry by turning unwanted marine rope into 3D printer filament.

Wasted Rope

Outside of the classroom, Marcos Gogolin devoted five years of his life to working out how to convert discarded marine rope into something beneficial. His inspiration for sustainability of the environment comes from a trip to Western Australia in 2011. Walking along the coast, he found the amount of wasted rope along the shoreline deplorable. As a result, he decided that he needed to do something about it.

Then, five months later a 3D printer found its way into the teacher’s hands. His school gave him the printer to help create courses that teach people how to print 3D objects. While initially feeling conflicted about the idea of using more plastic with 3D printing filaments, Gogolin had his ‘eureka’ moment. He figured that it might be possible to come up with a method to melt the wasted marine rope into a consistent and functional filament. As a result of this idea, he concluded that both the environment and the new technology would benefit.

Experimenting

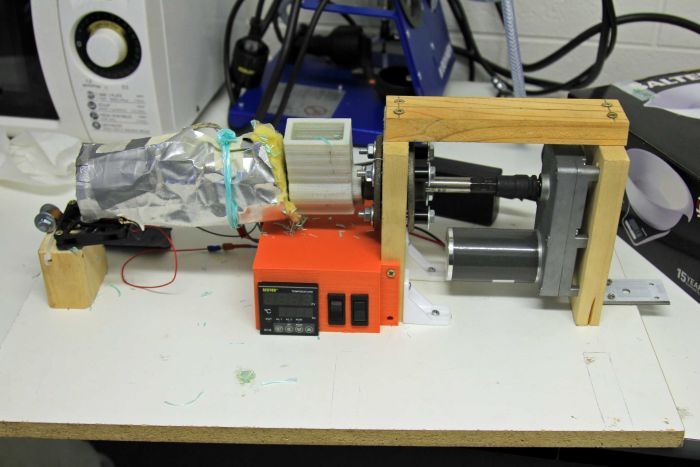

His initial experiments weren’t all that successful. Mr. Gogolin began using hot glue guns bought from a local hardware store. As a result of the initial failures, he quickly realized that he needed a more powerful industrial-grade glue gun. After a collaborative effort involving students at his school, Mr. Gogolin created an impressive DIY machine that converts plastic offcuts of marine rope into a working printer filament.

Ultimately, the method needs more fine-tuning before it could be implemented on a larger industrial scale. But it is yet another impressive innovation that shows how it’s possible to develop a symbiotic relationship between the environment and 3D printing.