A German research team from the Fraunhofer IPA, together with other companies and institutions, has found that e-bike motors can be remanufactured in a circular economy approach.

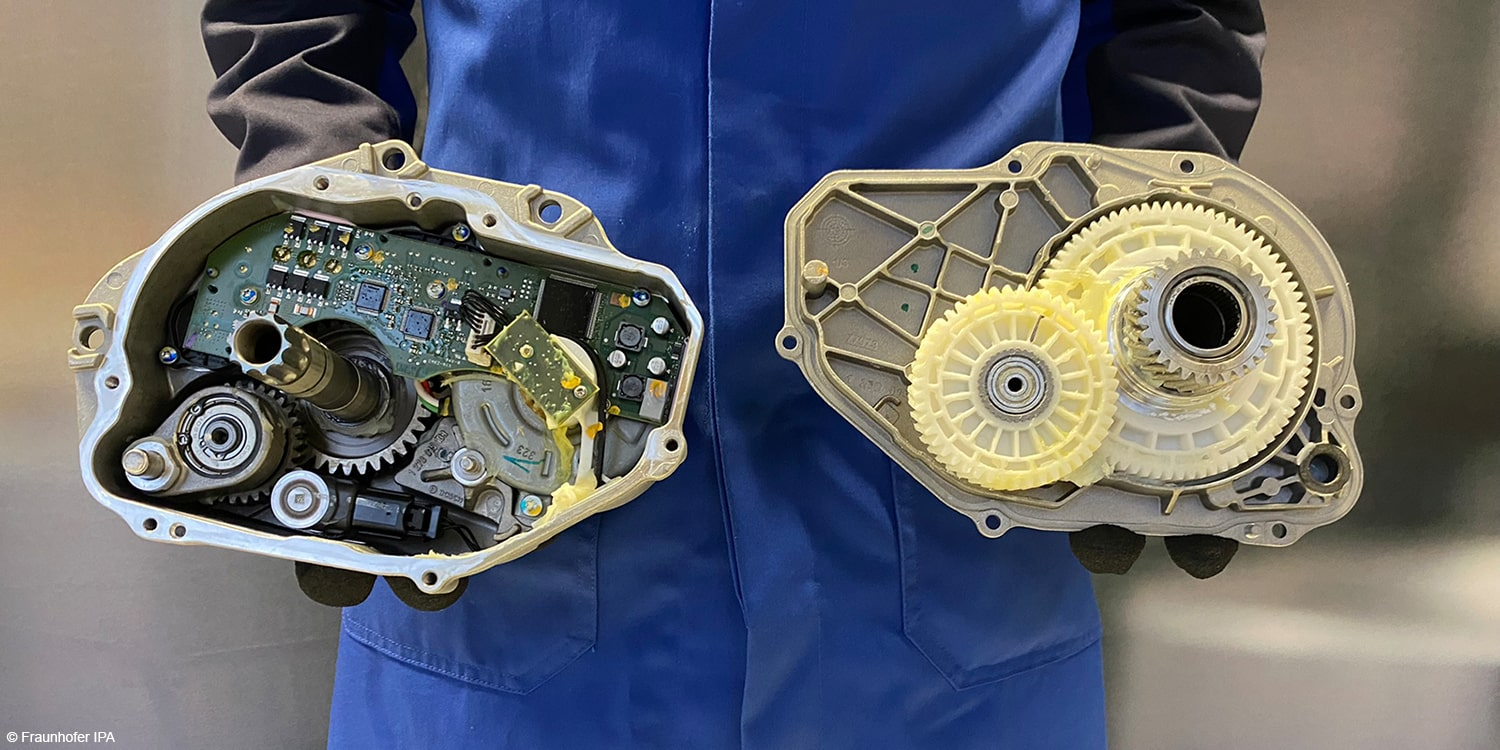

The researchers conducted the AddRE-Mo project to investigate the technical feasibility and ecological and economic potential of remanufacturing electric bike motors. They examined the probability of failure of established e-bike manufacturers’ motors and tested whether spare parts with high wear rates, such as gears and torque supports, could be manufactured additively.

They then selected materials and additive processes and tested the components’ service life, noise development, and temperature resistance in specially developed test stands and under real loads. They found that remanufacturing delivers a bike motor that is on par with a newly manufactured motor in terms of quality and offers a potential cost saving of 30 to 40 per cent for comparable components.

Given the rising sales figures, with electric bikes accounting for 48 percent of sales in the overall bicycle market in 2022, more and more e-bikes are on the road in Germany. However, a broken motor is usually exchanged as a whole for a new unit, even though it may only be one gear that’s faulty.

The researchers see great potential for the approach, and to consolidate their results, they will implement the process chain of remanufacturing electric bike motors in the new RemanLab learning factory at the Fraunhofer IPA in Bayreuth, which will open on May 23, 2023.

Come and let us know your thoughts on our Facebook, Twitter, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.