Soft robots have long been constructed using synthetic polymers, rubbers, and plastics, but concerns about their environmental impact have sparked a quest for more sustainable alternatives. In a new development, a team of interdisciplinary researchers at Carnegie Mellon University has pioneered a novel method of fabricating biodegradable actuators for marine applications using materials derived from common brown seaweeds.

Seaweed Bio-ink

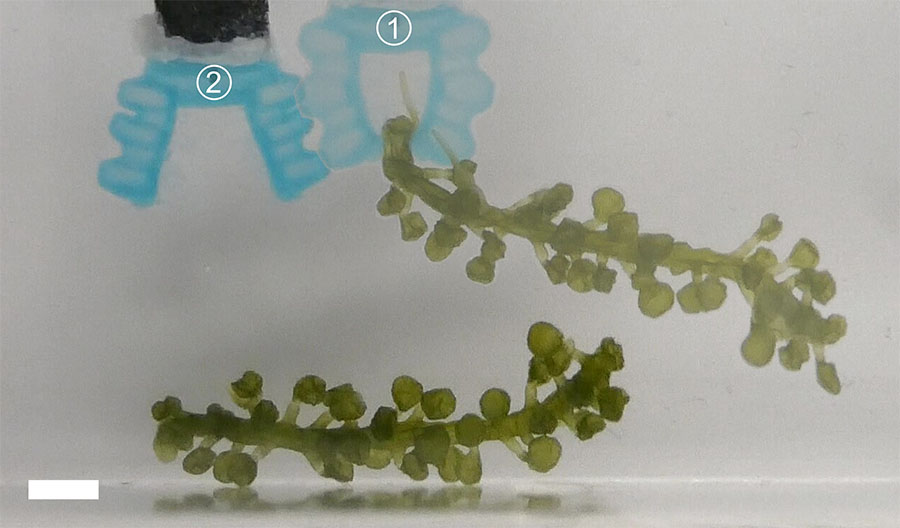

Led by faculty members Victoria Webster-Wood and Adam Feinberg, in collaboration with Carmel Majidi and Lining Yao, the team harnessed the power of the FRESH Printing method to create water-tight structures with unique properties. By employing a bio-ink derived from seaweed, they successfully developed small-scale, highly flexible actuators capable of extending, bending, and twisting. These actuators can also be combined to form structures for gripping and positioning.

The innovation lies in the seaweed-based inks, which utilize calcium to crosslink and form gels. This attribute allows the actuators to change shape and stiffness by adjusting the degree of crosslinking. Moreover, the actuators exhibit impressive biodegradability, breaking down in natural ocean conditions within a mere seven days. Notably, they are also safe for marine organisms to consume, minimizing the risk to the environment if lost or damaged.

Under the guidance of Webster-Wood, Feinberg, Majidi, and Yao, MS-BRIDGE Fellow Avery Williamson and GEM University Fellow Ravesh Sukhnandan are pushing the boundaries of actuator performance in natural environments while exploring the expansion of this printing approach to complete robotic structures.

“We are very excited to expand the fabrication capability of the FRESH Printing method and optimize it for soft robotic applications,” said Wenhuan Sun, a recent Ph.D. student in mechanical engineering.

“The unique benefits of FRESH make it possible to create robotic structures with a combination of unusual properties.”

By bridging the gap between advanced soft robotic structures and environmental sustainability, the team’s biodegradable actuators offer a promising solution. The ongoing development of these eco-friendly technologies signifies a step forward in creating tools and methods with clear sustainable applications.

Come and let us know your thoughts on our Facebook, Twitter, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.